AMIPAK

AMIPAK

AMIPAK thermo-shrink vacuum bags provide reliable, high-barrier packaging for the food industry. Their glossy finish and transparency help showcase products attractively. Designed for use with vacuum chamber machines, they fit a wide range of applications. These vacuum bags are available for food producers in both Canada.

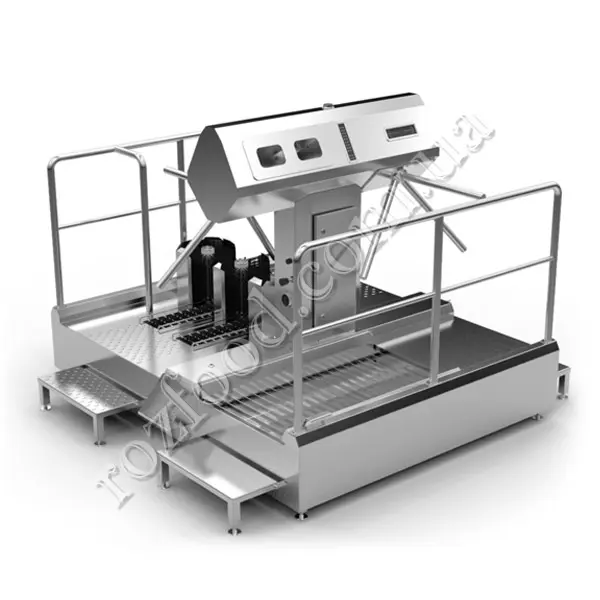

We have a wide range of equipment for food manufacturers in Canada and USA in our catalogue. Whether you are in the meat, dairy, pet food or any other industry, you can find equipment that will improve your bottom line and automate your processes. Also for sausage producers we have a wide range of clips, loops and casings at the best prices on the market, and the most important thing is that our consumables are universal and suitable for any equipment of our competitors.

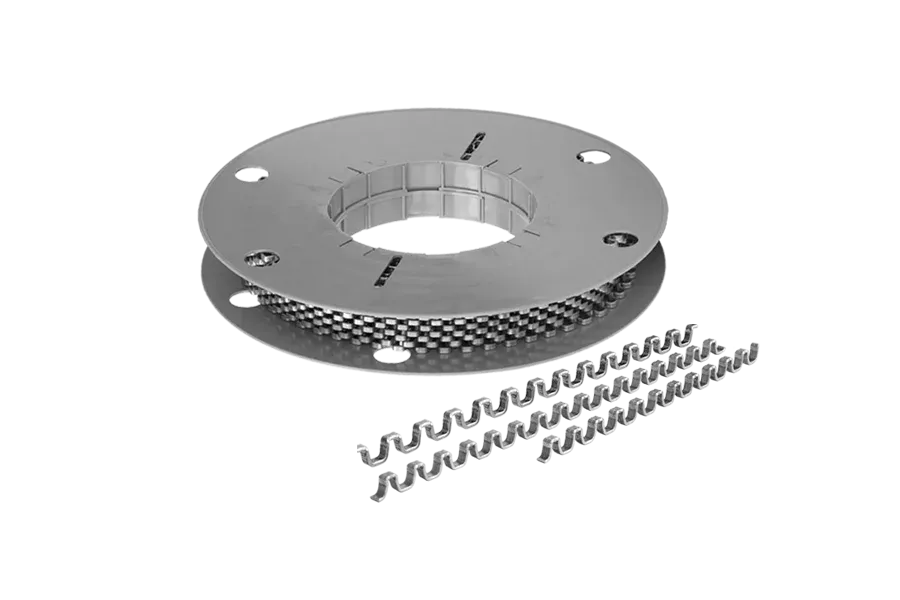

AMIPAK casing made on advanced equipment, which ensures:

- continuous control of all parameters.

- maximum automation of the production process.

Basic quality characteristics and test conditions for the AMIPAK casing of all types detailed in the specifications.

Printing

Casing can be printed on one side or two sides. Number of printing colors is from 1+0 to 6+6. CMYK printing is optional.

Printing: the curved casings can be used only for:

- single-side printing with ‘face register’;

- double-side printing without register (i.e., when the artwork is background printing).