Inwestpol Injector ANS-62 , ANS-108

Injectors ANS-62 and ANS-108 are devices for brine injection into the meat through a needle. They can be used for injecting into various types of meat: poultry, pork and beef, with and without bones. The devices are equipped with two injection heads and two centrifugal, stainless steel pumps. The device is equipped with a microprocessor that allows to set the selected parameters of the machine, such as the working conveyor belt, number of beats and pump productivity. Set parameters can be stored in the processor memory, and it ensures repeatability of the injection process. The device is equipped with a set of sieves to allow pre-cleaning of the brine but also, it is designed to work with a slotted rotating filter that provides higher filtering accuracy.

- Stainless acid-proof steel

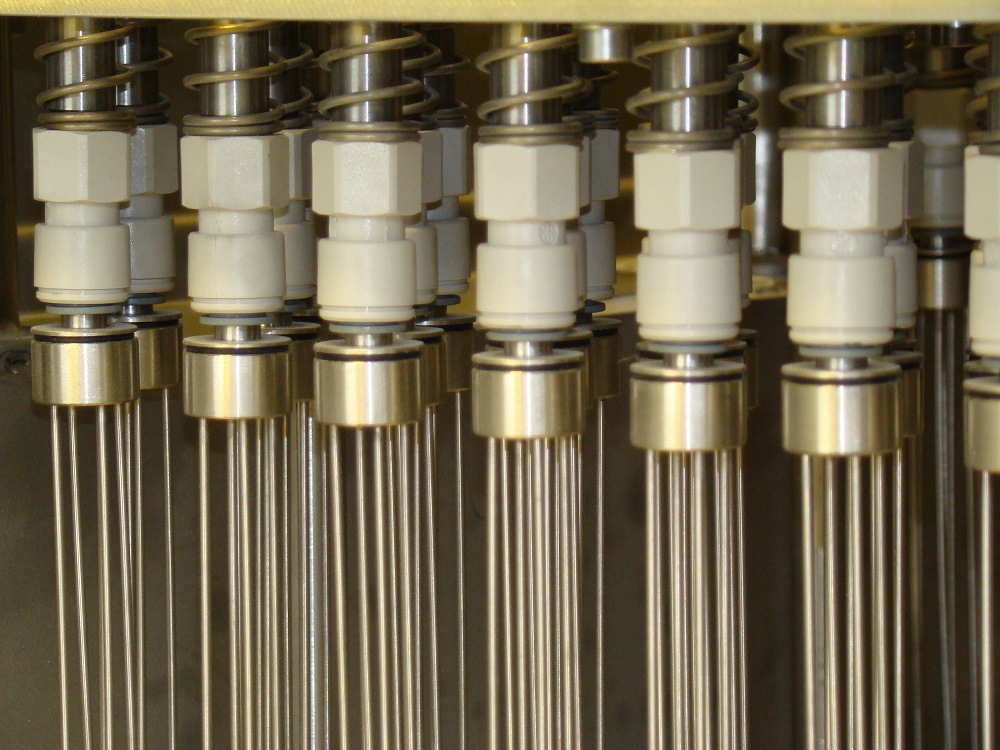

- “Fast connection” needles

- Two injecting heads with needle chests in 3 raws.

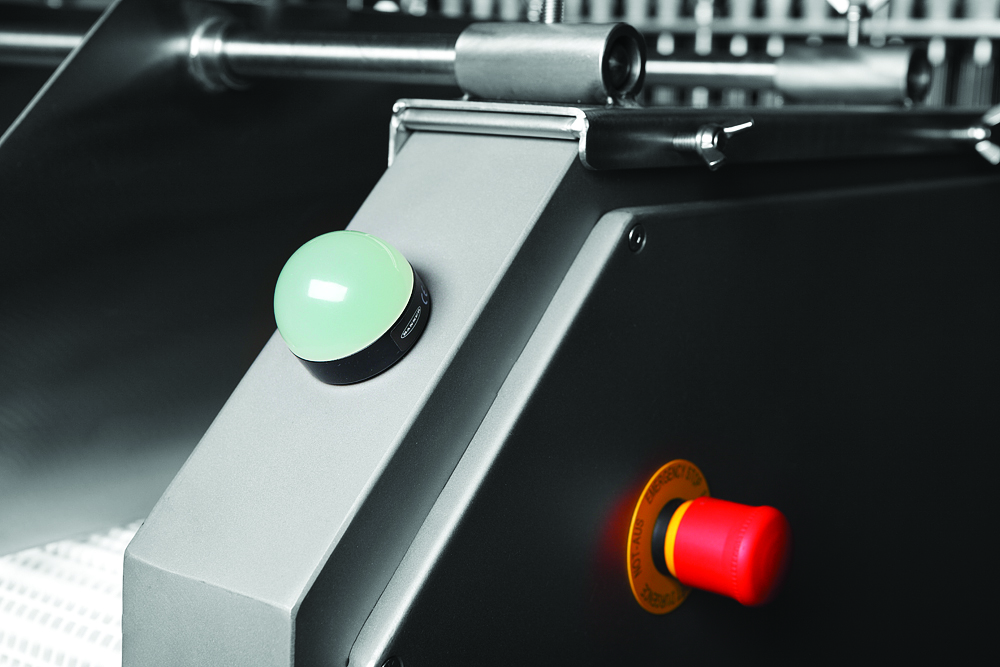

- Mitsubishi microprocessor with a touchscreen control panel

- Adjustable pump effectiveness 0-100%

- Smooth regulation of the conveyor belt jumps in a range of 0-200mm

- Adjustable needle head speed in a range of 0-60 beats/min

- Conveyor belt made of 700mm long polypropylene – ( easy to remove and clean)

- Two stainless steel pumps

- Automatic needle washing

- The machine is adapted to work with a rotary gap filter

- Possibility to inject 1-100% of brine.

- ModelANS-62ANS-108

- Number of needles, pcs62/124/248108/216/432

- Number of needle nests, pcs62108

- Productivity, kgAbout 3500About 4500

- Conveyor belt width, mm400500

- Max. needle lift height, mm250250

- Brine pressure, bar0.5-40.5-4

- Power, kW7.57.5

- Voltage, V/Hzby customer's request

- Dimensions (L * B * H), mm1900 x 900 x 22002200 x 1000 x 2200

- Weight, kg700900

Installations, customers’ personnel training, warranty and after warranty service provided by KOMPO North America Inc. certified technicians.

Consultations by phone and video calls are free of charge.

KOMPO North America Inc. is happy to provide its customers with the longest Warranty on the market. The extended warranty plans are available too.

Please, ask your sales person.

The spare parts are in stock in North and Latin American offices. Spare parts kits are available for any of the equipment you purchase from KOMPO North America Inc.

We are happy to help our customers succeed in their business, supplying the right and reliable machines to manufacture food products.

Please, contact us for details at [email protected] or Toll Free: 1-888-307-5330.

- Stainless steel design;

- Universality, simplicity and reliable operation;

- Longest Warranty in the industry;

- Low operation costs;

- High flexibility.