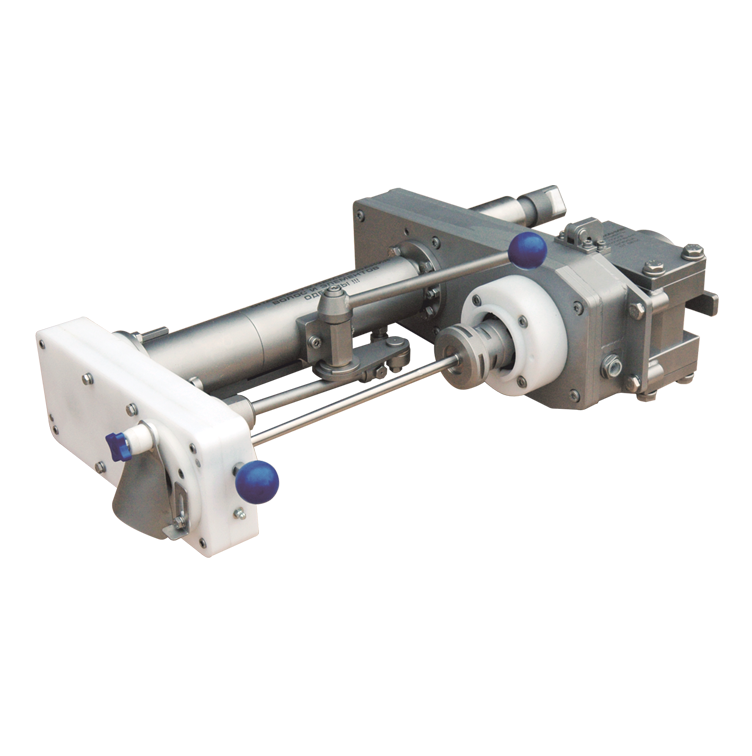

Linking Devices FPK, FPL, FPS, FPR

The precise portioning of forcemeat filled into casings is very important in today’s meat processing industry. Growing numbers of supermarkets, fast food restaurants and other retail businesses are paying more and more attention to precise product weight. The KOMPO linker and portioning device addresses this demand through the precise filling of wieners, hot dogs, and other small sausages with automatic twisting between sausage links. Combined with KOMPO fillers, the linking device ensures high-quality filling, great presentation, and high output on various types of casings.

- Stainless steel design

- Meets all hygiene requirements in food industry

- Easy clean

- Dedicated motor for linker – long motor life

- Several sizes of horns available: 10mm, 12.5mm, 16.9mm, 20mm

- Link any type of casing

- Vacuum fillers modelsMINI 1500

- Casing typeartificial, collagen, cellulose, polyamide

- Dosage range adjustment, gr25-120

- Installed power, kW0,55

- Output with artificial casing (dose 50 gr), kg/hup to 570

- Filling tubes, mmhot dog Ø 10 orderhot dog Ø 12,5 +frank furter Ø 16,9 +frank furter Ø 20 order

- Dimensions, mm: L*W*H835*645*245

- Net weight, kg52

- Vacuum fillers modelsOPTI 2000

- Casing typeartificial, natural

- Dosage range adjustment, gr25-120

- Installed power, kW1,1

- Output with artificial casing (dose 50 gr), kg/hup to 1160

- Filling tubes, mmhot dog Ø 10 orderhot dog Ø 12,5 +frank furter Ø 16,9 +frank furter Ø 20 order

- Dimensions, mm: L*W*H835*645*245

- Net weight, kg52

- Vacuum fillers modelsOPTI 2000-01

- Casing typeartificial, natural

- Dosage range adjustment, gr25-120

- Installed power, kW1,1

- Output with artificial casing (dose 50 gr), kg/hup to 1160

- Filling tubes, mmhot dog Ø 10 orderhot dog Ø 12,5 +frank furter Ø 16,9 +frank furter Ø 20 order

- Dimensions, mm: L*W*H835*645*245

- Net weight, kg52

- Vacuum fillers modelsMAXI 3000-11/13

- Casing typeartificial, natural

- Dosage range adjustment, gr25-120

- Installed power, kW1,5

- Output with artificial casing (dose 50 gr), kg/hup to 1250

- Filling tubes, mmhot dog Ø 10 +hot dog Ø 12,5 +frank furter Ø 16,9 +frank furter Ø 20 order

- Dimensions, mm: L*W*H835*645*245

- Net weight, kg52

- Vacuum fillers modelsMASTER 1100-02/03

- Casing typeartificial, natural

- Dosage range adjustment, gr10-300

- Installed power, kW5,9

- Output with artificial casing (dose 50 gr), kg/hup to 1450

- Filling tubes, mmhot dog Ø 10 +hot dog Ø 12,5 +frank furter Ø 16,9 +frank furter Ø 20 +

- Dimensions, mm: L*W*H605*420*240

- Net weight, kg27

Installations, customers’ personnel training, warranty and after warranty service provided by KOMPO North America Inc. certified technicians.

Consultations by phone and video calls are free of charge.

KOMPO North America Inc. is happy to provide its customers with the longest Warranty on the market. The extended warranty plans are available too.

Please, ask your sales person.

The spare parts are in stock in North and Latin American offices. Spare parts kits are available for any of the equipment you purchase from KOMPO North America Inc.

We are happy to help our customers succeed in their business, supplying the right and reliable machines to manufacture food products.

Please, contact us for details at [email protected] or Toll Free: 1-888-307-5330.

- Stainless steel design

- Meets all hygiene requirements in food industry

- Easy clean

- Dedicated motor for linker – long motor life

- Several sizes of horns available: 10mm, 12.5mm, 16.9mm, 20mm

- Link any type of casing