Semi-auto Pneumatic Double Clipping Machine KN-22S

The semi-automatic double clipping machine KN-22S is reliable, efficient, and easy-to-use. They are designed for clipping all artificial and natural casings, supporting output of up to 420kg/h. The KN-22Sprovide the ability to clip a wide range of products and are ideal for small, medium, and large scale production facilities.

- Dosing of the weight of the sausage being filled using a “timer” and a “flag” for controlling the filler from the clipper or using the function of dosing by the dosing filler;

- possibility of unitization with a filler of any manufacturer; adjustment of sausage filling density;

- adjustment of the pusher travel speed at the moment of clip application;

- manual clamping drive and pneumatic clipping drive; automatic or manual control of the cut-off blade drive; changing to various casing diameters without disconnecting the clipper from the filler;

- possibility of using A type, small clips, (on custom-built machines); universality, simple maintenance, reliability and low operating costs.

- Three dosing methods —filler signal; timer; flag signal (mechanical or optical);

- compatibility with a filler of any manufacturer;

- regulation of stick filling density and overfilling;

- adjustable pusher speed;

- manual clamping drive and pneumatic clipping drive;

- automatic or manual activation of the cut-off knife;

- fast and easy readjustment to various casing sizes;

- versatility, easy maintenance, reliability, and low operating costs.

- Dosing of the weight of the sausage being filled using a “timer” and a “flag” for controlling the filler from the clipper or using the function of dosing by the dosing filler;

- possibility of unitization with a filler of any manufacturer; adjustment of sausage filling density;

- adjustment of the pusher travel speed at the moment of clip application;

- manual clamping drive and pneumatic clipping drive; automatic or manual control of the cut-off blade drive; changing to various casing diameters without disconnecting the clipper from the filler;

- possibility of using A type, small clips, (on custom-built machines); universality, simple maintenance, reliability and low operating costs.

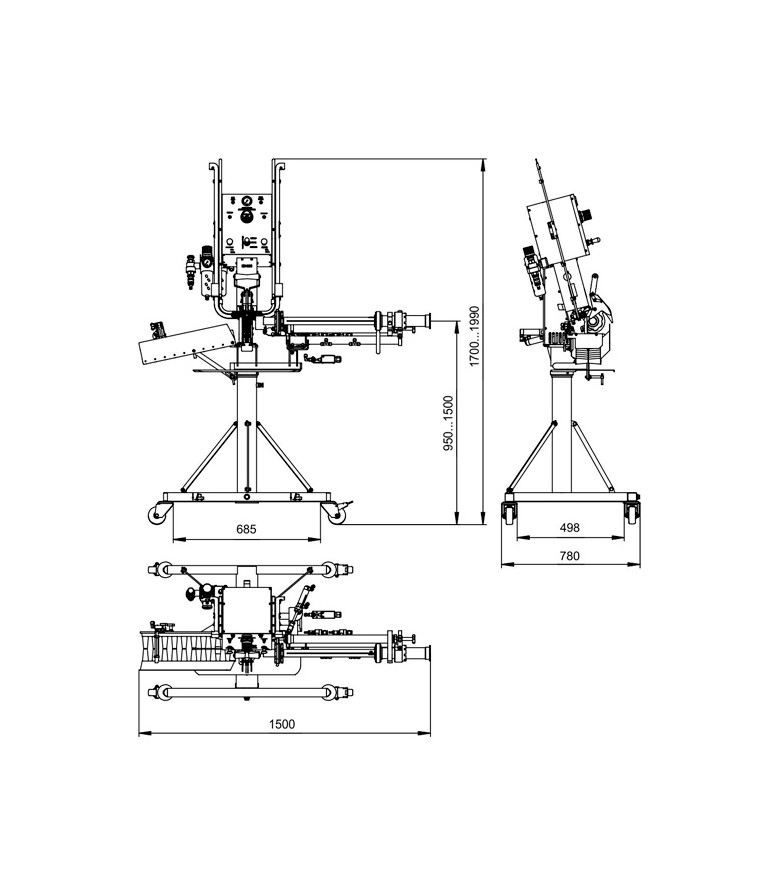

- ModelKN-22S

- Model versionFloor standing

- Clipping cycle, sec1.5-3

- Casing caliber, mm40-80

- ClipsB, BP types (A type for small calibers)

- Clamping driveManual

- Clipping drivePneumatic

- Looping systemManual (loops in bunches)

- Date markingOptional

- Distance from floor to filling tube axle, mm950 - 1150

- Air pressure in the clipper’s operating pneumatic circuit, Mpa0.6-0.7 Mpa

- Air consumption, max., l/cycle1.2

- Overall dimensions, mm, maximum: Length*Width*Height1500mm*780mm*1990mm

- Net weight, kg75 kg

Installations, customers’ personnel training, warranty and after warranty service provided by KOMPO North America Inc. certified technicians.

Consultations by phone and video calls are free of charge.

KOMPO North America Inc. is happy to provide its customers with the longest Warranty on the market. The extended warranty plans are available too.

Please, ask your sales person.

The spare parts are in stock in North and Latin American offices. Spare parts kits are available for any of the equipment you purchase from KOMPO North America Inc.

We are happy to help our customers succeed in their business, supplying the right and reliable machines to manufacture food products.

Please, contact us for details at [email protected] or Toll Free: 1-888-307-5330.

- Dosing of the weight of the sausage being filled using a “timer” and a “flag” for controlling the filler from the clipper or using the function of dosing by the dosing filler;

- possibility of unitization with a filler of any manufacturer; adjustment of sausage filling density;

- adjustment of the pusher travel speed at the moment of clip application;

- manual clamping drive and pneumatic clipping drive; automatic or manual control of the cut-off blade drive; changing to various casing diameters without disconnecting the clipper from the filler;

- possibility of using A type, small clips, (on custom-built machines); universality, simple maintenance, reliability and low operating costs.