N&N Nadratowski Cooking mixers MIX COOK SERIES

The MIX Cook series is an innovative two-shaft cooking mixers equipped with a steam or oil heating jacket as standard, which allows for quick and even mixing and cooking of many products. It is currently one of the best solutions in the field of food heat treatment, which allows to achieve high quality, reproducible results and to meet the highest standards of food production safety. Thanks to the possibility of equipping the machine with paddle or ribbon shaft s with the option of equipping it with an innovative system of scrapers preventing burning, it can be used for cooking various products from sauces, purées, baby food, vegetables, rice, grains or minced meat and off all.

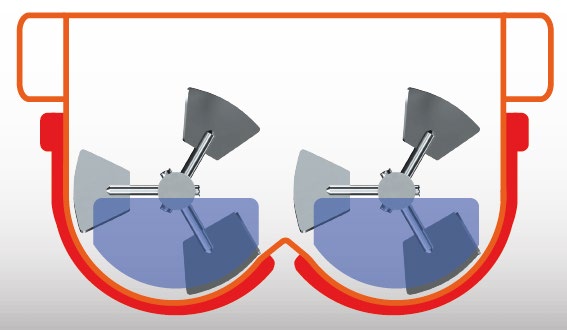

PARALLEL TWIN SHAFTS

In the MIX Cook series mixers, the mixing process is carried out by two twin parallel paddle or ribbon shafts, placed at the same heights. The characteristic feature of this series of machines is the possibility to set the speed and direction of rotation independently for each shaft.

UNLOADING

The N&N’s mixers of the MIX Cook series, thanks to the two built-in discharge flaps and low clearance between the shaft s and the mixing bowl, enable fast and safe ejection of the cooked product, while leaving only minimal amount of product between the individual batches.

CONTROL

The MIX Cook series mixers are equipped as standard with a colour HMI touch screen, which is user-friendly and intuitive to use. Dedicated software with advanced cooking options and process monitoring and control equipment allows you to maximize product efficiency. Possibility of recipe management and access control allows to maintain repeatability of individual product batches.

SCRAPERS

The MIX Cook series mixers can be optionally equipped with an innovative system of scrapers consisting of a springy claw and a special high-temperature-resistant plastic, which perfectly scrape the product from the whole heating surface of the jacket and prevent the product from burning.

DIRECT STEAM INJECTION

All MIX Cook series machines can be equipped with a system of hygienic nozzles for direct steam injection into the product, which can accelerate the process even several times without the effect of burning.

- Model500 SV750 SV1000 SV1250 SV1600 SV

- Tank capacity, l500750100012501600

- Max. Charge, l.3755607509401200

- Control paneltouch control paneltouch control paneltouch control paneltouch control paneltouch control panel

- Motors power, kW2x32x5.52x5.52x5.52x7.5

- Shaft rotation speed, rpm5-404-364-304-303-28

- Busch optional vacuum pump, m3/h (option available with vacuum type of mixer)2545457272

- Steam trainIncluded - Spirax SarcoIncluded - Spirax SarcoIncluded - Spirax SarcoIncluded - Spirax SarcoIncluded - Spirax Sarco

- Minimum steam inlet pressure, bar33333

- Max temperature of jacket, °С120120120120120

- 500 SV Dimensions (L * B * H), cm260x130x165

- Weight, kg1220

- 750 SV Dimensions (L * B * H), cm265x145x181

- Weight, kg1620

- 1000 SV Dimensions (L * B * H), cm270x155x195

- Weight, kg1920

- 1250 SV Dimensions (L * B * H), cm290x166x202

- Weight, kg2070

- 1600 SV Dimensions (L * B * H), cm340x176x205

- Weight, kg3220

- Model2100 SV2600 SV3200 SV3800 SV4800 SV

- Tank capacity, l21002600320038004800

- Max. Charge, l.15751950240028503600

- Control paneltouch control paneltouch control paneltouch control paneltouch control paneltouch control panel

- Motors power, kW2x112x112x152x152x22

- Shaft rotation speed, rpm3-283-253-222-202-18

- Busch optional vacuum pump, m3/h (option available with vacuum type of mixer)100100160205205

- Steam trainIncluded - Spirax SarcoIncluded - Spirax SarcoIncluded - Spirax SarcoIncluded - Spirax SarcoIncluded - Spirax Sarco

- Minimum steam inlet pressure, bar33333

- Max temperature of jacket, °С120120120120120

- 2100 SV Dimensions (L * B * H), cm371x192x225

- Weight, kg3720

- 2600 SV Dimensions (L * B * H), cm373x205x227

- Weight, kg4570

- 3200 SV Dimensions (L * B * H), cm381x212x252

- Weight, kg5620

- 3800 SV Dimensions (L * B * H), cm405x229x282

- Weight, kg6540

- 4800 SV Dimensions (L * B * H), cm436x232x302

- Weight, kg7340

Installations, customers’ personnel training, warranty and after warranty service provided by KOMPO North America Inc. certified technicians.

Consultations by phone and video calls are free of charge.

KOMPO North America Inc. is happy to provide its customers with the longest Warranty on the market. The extended warranty plans are available too.

Please, ask your sales person.

The spare parts are in stock in North and Latin American offices. Spare parts kits are available for any of the equipment you purchase from KOMPO North America Inc.

We are happy to help our customers succeed in their business, supplying the right and reliable machines to manufacture food products.

Please, contact us for details at [email protected] or Toll Free: 1-888-307-5330.

- Stainless steel design;

- Universality, simplicity and reliable operation;

- Longest Warranty in the industry;

- Low operation costs;

- High flexibility.