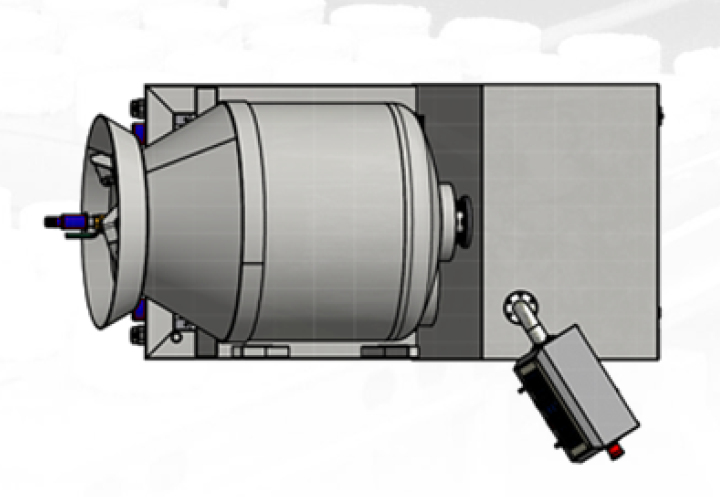

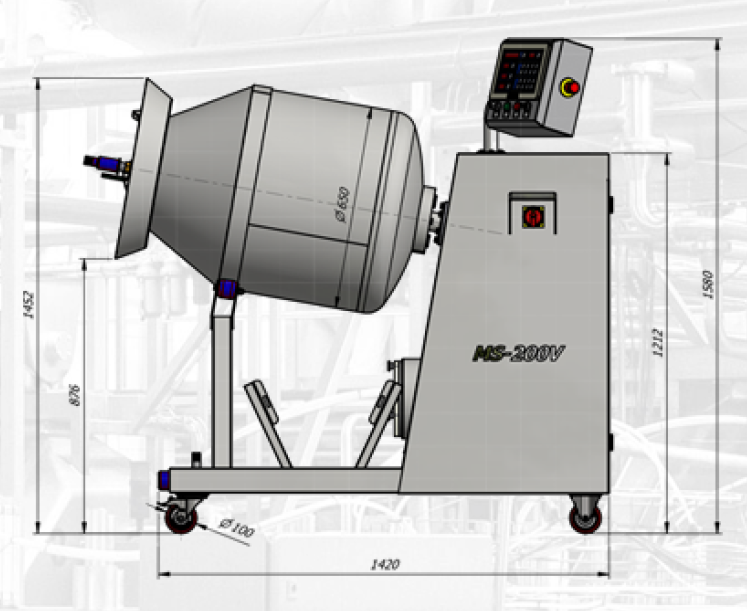

Vacuum tumbler MS-200V

Vacuum tumbler MS-200V is designed to be used in small and medium sized meat plants to massage, marinade, pickle and flavor in vacuum environment for maximum saturation of spices and brine to achieve high-quality meat products. This machine equipped with 200 l barrel which allows load up to 120kg of products. Main drive power of 0.55 kWH provides 1-9 rot. /min, so meat does not damage during the process. Power of installed vacuum pump 0.5kwh gives productivity of 20 m3/h and provides high efficiency of the proper massaging process. The use of high-quality stainless steel allows the machine to be kept clean and properly hygienic in production.

- ModelMS-200V

- Barrel capacity, l200

- Max. Charge, kg120

- Arm rotation speed, rot./min1-8

- Automatic vacuum regulation, %0-99

- Automatic process time regulation, h0-24

- Vacuum pump productivity, m3/h20

- Vacuum pump power, kW0.5

- Main drive power, kW0.55

- Total power, kW1

- Voltage, V/Hzby customer's request

- Dimensions (L * B * H), mm1420 x 754 x 1580

- Weight, kg300

Installations, customers’ personnel training, warranty and after warranty service provided by KOMPO North America Inc. certified technicians.

Consultations by phone and video calls are free of charge.

KOMPO North America Inc. is happy to provide its customers with the longest Warranty on the market. The extended warranty plans are available too.

Please, ask your sales person.

The spare parts are in stock in North and Latin American offices. Spare parts kits are available for any of the equipment you purchase from KOMPO North America Inc.

We are happy to help our customers succeed in their business, supplying the right and reliable machines to manufacture food products.

Please, contact us for details at [email protected] or Toll Free: 1-888-307-5330.

- Stainless steel design;

- Universality, simplicity and reliable operation;

- Longest Warranty in the industry;

- Low operation costs;

- High flexibility.