Thermoformer SC 190

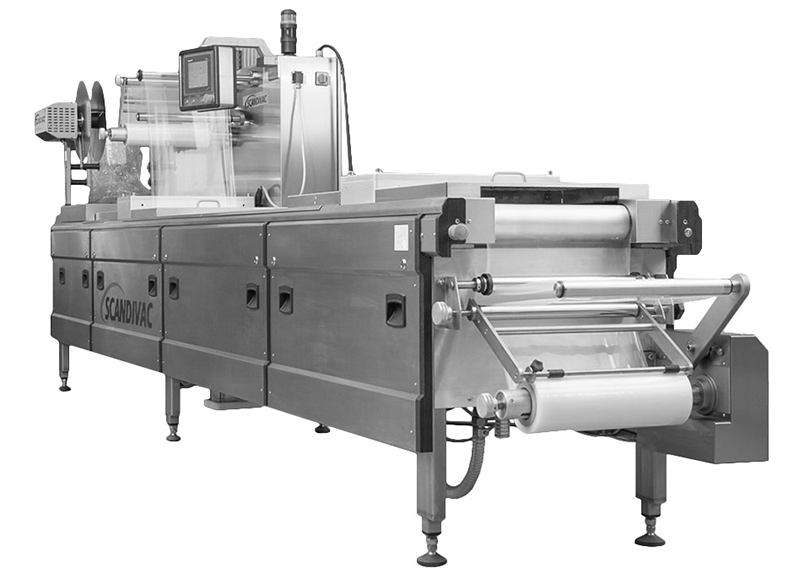

SCANDIVAC SC 190 is usable for small amount of products packaging. With very compact dimensions, it is very useful in limited areas.

Every single machine is manufactured according to the individual request; therefore it totally conforms with customers’ needs and wishes. By using tested technologies and electronical and pneumatic spare parts of European well known manufacturers, packaging machines provide safe, precise and stable work during many years of operation.

SCANDIVAC SC 190 can be used to pack wide range of products

Food – packing of meat, fish, salads, cheese, vegetables and other products

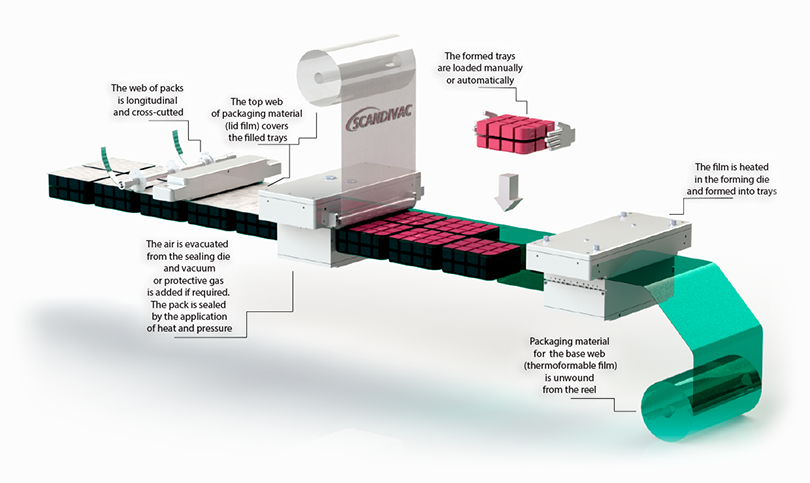

Type of packaging

• Only sealing of the package

• Vacuum and sealing

• Vacuum, gas and sealing

• „Skin” packaging

Types of cutting

• Longitudinal and cross-cutting

• Shape cutting

• Longitudinal perforation

• Cross-cutting perforation

Types of forming

• Only with compressed air

• With compressed air and vacuum

• With pre-heating of film

• With pre-heating of film and plugs

• Posiforming

Control system

• Colourful LCD touch screen

• Control elements from SMC Pneumatics, Schneider Electric, Allen Bradley, Busch and others

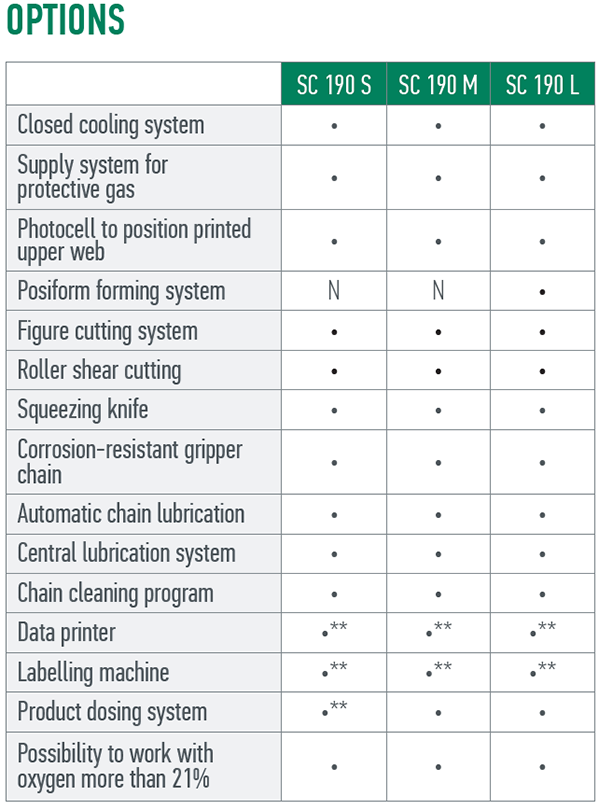

Potential options for SCANDIVAC machines

• Labeller

• Data printer

• Dosing system

• Pad placer

- Solid stainless steel frame, for safe transportation and for strengthening of systems and mechanisms.

- Freely variable distance between moulds, giving a possibility to use dies with different cut-off lengths.

- Durable gripper chain guides casing.

- 4 or 6 point independent lifting mechanisms for dies with pneumatic drive and grease lubrication from a central location. Made from stainless steel and its moving elements are connected with bearings.

- All SCANDIVAC machines are equipped with servo drive system for gripper chain.

- Most of the spare parts are freely available on the market.

- Specifications

- Types of cutting

- Types of forming

- Details of packages

- Specification of films

- Cross cutting

- Longitudinal cutting

- Dimensions

- ModelSCANDIVAC SC 190

- Cut-off length, mmWithout preheating: up to 800 mmWith preheating: up to 600 mm

- Longitudinal and cross-cutting

- Shape cutting

- Longitudinal perforation

- Cross-cutting perforation

- Only with compressed air

- With compressed air and vacuum

- With pre-heating of film

- With pre-heating of film and plugs

- Posiforming

- Hanging holeoval or round

- Hanging hole“euroslot”

- Film width (mm):from 320 up to 600 mm

- Top filmflexible film, paper, folio

- Top film Thicknessup to 100 microns

- Bottom film: rigid film, flexible film, folioThickness up to1000 microns

- Printed Top film

- Cross cutting unit for flexible filmstraight cut

- Cross cutting unit for flexible filmzig-zag cut

- Cross cutting unit for rigid filmwith round cornern

- Rotary knife assembly

- Squeezing knife assembly

- Roller shear cutting assembly – line cutting

- Roller shear cutting assembly – strip cutting

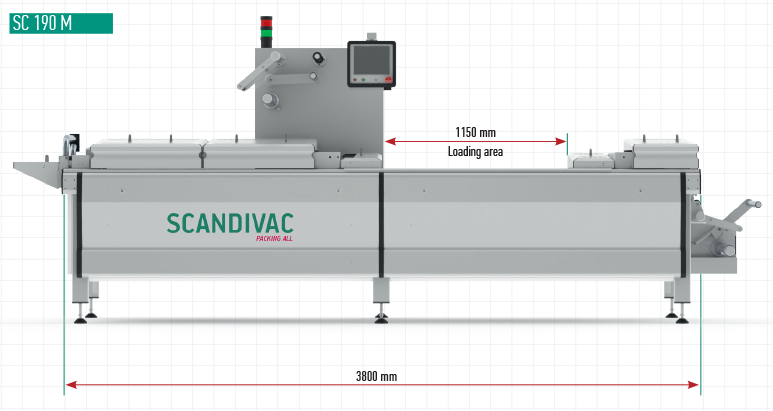

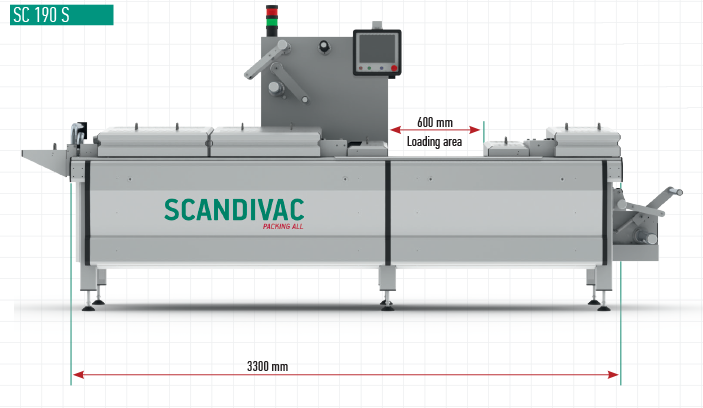

- Machine Length mm:SC 190 S: 3800 mmSC 190 M: 4300 mmSC 190 L: 4800 mm

Installations, customers’ personnel training, warranty and after warranty service provided by KOMPO North America Inc. certified technicians.

Consultations by phone and video calls are free of charge.

KOMPO North America Inc. is happy to provide its customers with the longest Warranty on the market. The extended warranty plans are available too.

Please, ask your sales person.

The spare parts are in stock in North and Latin American offices. Spare parts kits are available for any of the equipment you purchase from KOMPO North America Inc.

We are happy to help our customers succeed in their business, supplying the right and reliable machines to manufacture food products.

Please, contact us for details at [email protected] or Toll Free: 1-888-307-5330.