Compatibility guide for sausage clips 2025: what is compatible with what?

Compatibility guide for sausage clips 2025: what is compatible with what?

Thinking about changing your clamp supplier in 2025?

You're not alone. Right now, meat processors and sausage makers across Canada and the US are feeling pressure from management to cut costs.

Challenge is to reduce costs in sausage and meat production. And one of the main areas for reduction is consumables such as sausage clips or loops, which are the most accessible item for savings.

“Are these clips compatible with our clipping machines?”

We would like to try to answer this question by examining the compatibility of sausage clips with popular clipping machines in 2025.

What does “clip compatibility” actually mean?

There are certain conditions under which you can consider clips to be fully compatible, namely:

- they fit smoothly into the magazine or guide of your clip applicator

- they feed evenly under load

- they close securely without deforming the body

- they prevent jamming or sticking

- they ensure repeatable results at production speed

You should understand that when changing clips, even universal ones, it is not just a matter of size — accuracy, material, and mechanical characteristics are also important.

How to confirm compatibility without downtime.

Process is as simple as possible: you need to test the new clips, and the instructions for this process are straightforward:

Request a sample from your local supplier (at Kompo North America, we always send free samples for testing to sausage manufacturers in Canada and the US).

Test on a non-critical line or at the end of a shift (in our experience, testing at the end of a shift is most convenient, as it does not involve potential time losses or equipment downtime).

Involve quality control specialists and line operators in the evaluation (it is very important to get several opinions from people who are directly involved in the production process. But don't forget about managers and business owners).

Check for jams, seal quality, and body integrity (depending on your product, you need to perform all tests, not just clipping. If you cook your product in ovens or it matures in special chambers, let the sausage finish completely and then you will have the full picture).

Record the results to support purchasing decisions.

Tip from experience: a clip that is “close enough” in size can still cause wear, breakage, or incorrect feeding of the clip or loop over time. Therefore, always check the quality of the equipment to prevent downtime.

During KOMPO North America Inc.'s entire time in the Canadian and US markets, we have encountered some problems with the alignment of the clip and the clipper. However, in 99 percent of cases, this was easily corrected by adjusting the clipper matrix, which allowed us to reduce costs by $20,000 to $30,000 per year without any production issues.

Why are more and more manufacturers switching to compatible clips?

In fact, there are many reasons for changing clips, but we believe that in 2025, it will not only be about cost savings (although these are significant, often 30–40%). It will also be about:

- Stable local market supply (A stable and large supplier warehouse and the right approach to purchasing avoid downtime due to stock shortages. At KOMPO North America Inc., we use a double insurance practice, which means that we have constant availability for existing customers and an additional warehouse with clips in case of unforeseen circumstances. )

- Recommendations for specific machines (Over 13 years, we have completely adapted our production to the needs of the Canadian and US markets. We have a wide range of clips of our own production that can work with absolutely any clipping machine on the US and Canadian markets).

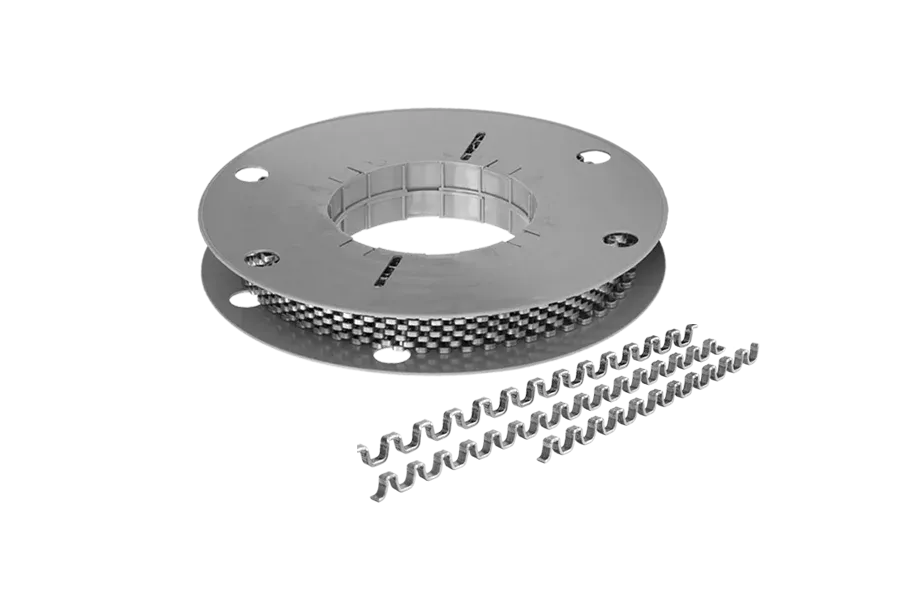

KOMPO North America Inc. offers a complete range of compatible clips:

- For clipping machines available on the market and in factories in Canada and the US

- Warehouse stock in Canada - We are located in London, Ontario, which is convenient for companies in Canada and the US, and delivery can be as fast as possible.

- Technical support for the right selection - our technical specialists not only help with clip selection, but can also help with troubleshooting. There have been many cases where our specialists have repaired and adjusted various equipment at our customers' production facilities. And it happens that clip machines can be from one brand and easily use our clips and loops.

Final thought: compatibility means control, insurance, and significant savings

The financial aspect is quite clear: you can reduce clamp costs by 30-50 percent simply by choosing the right supplier.

Another factor is protecting your production line from external factors that change not just every day, but even every hour.

When you find a supplier with the most compatible clips, such as KOMPO North America Inc., you will get:

- Equipment runs cleaner - this also happens, especially with older clip feeders, when support for older models ends.

- Reduced maintenance—once you have set up compatibility and perform inspections after each shift, you will enjoy long periods of trouble-free operation and no downtime.

- Quality control issues disappear.

- And costs are reduced.

Don't guess. Don't take chances.

Before replacing, check compatibility and order samples before placing large orders. And to get even more accurate answers to all your questions, you can always invite the supplier's representatives to conduct tests with you.