How Spiral Freezer Systems Are Transforming Food Processing in Canada & the USA

This article is intended for fast food manufacturers in Canada and the United States who are involved in the industrial-scale production of such products. In this type of production, it is important to consider an important factor: product freezing.

In the North American food industry, high-performance freezing technologies are critical to ensuring quality, speed, and consistency in production.

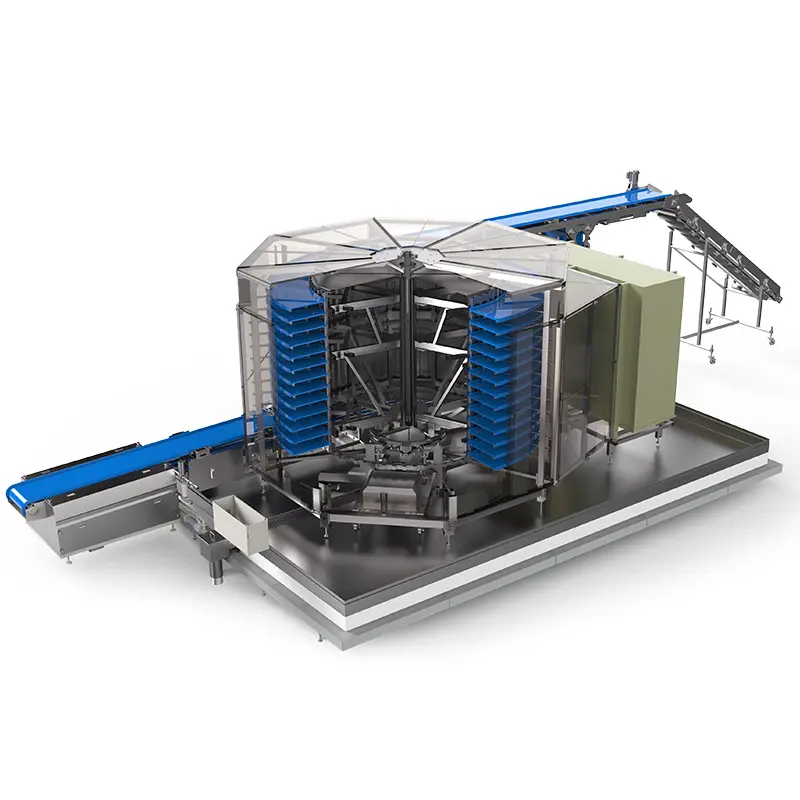

Introducing spiral freezing systems for fast food manufacturers, including those used for spiral freezing and spiral blast freezing, are becoming the industry standard. These and other solutions enable the creation of compact cooling units, rapid temperature reduction, and consistent IQF (individual quick freezing) performance, which is ideal for meat, seafood, bakery, and ready-meal production lines.

Market trends and industry research

There are studies that provide specific statistics related to the industrial freezer market. Global demand for spiral freezers is growing. Spiral freezer market was estimated at approximately $4.19 billion in 2024 and is projected to grow to $8.76 billion by 2033, with a compound annual growth rate of ~8.5%.

Let's take a look at the North American market (USA, Canada, Mexico), which is growing at ~4.3% per year and is expected to be the dominant region until 2030. The US market dominated the North American Spiral Freezer Market by Country in 2022 and would continue to be a dominant market until 2030, thereby achieving a market value of $1,167 million by 2030. The Canada market is experiencing a CAGR of 6.7% during (2023-2030). Additionally, the Mexico market would showcase a CAGR of 5.8% during (2023-2030).

Spiral freezer manufacturers report energy savings of 30–60% compared to traditional defrosting/freezing methods, as well as significant reductions in cleaning time and water consumption. Such efficiency is crucial as processors face rising utility costs and pressure from environmental organizations demanding the achievement of sustainability goals.

Main characteristics and design features

Main design features of spiral freezers

Each freezer has a unique engineering design. Our spiral freezers for the fast food industry are designed specifically for the US and Canadian markets and have a number of distinctive features.

Let's take a look at these advantages:

- The multi-level belt configuration ensures continuous freezing with optimized airflow.

- Built-in defrosting zones and temperature zones support different types of products and allergen separation.

- Stainless steel exterior and CIP-compatible components ensure hygiene and durability.

Brief description of characteristics and advantages

- Aerofreeze airflow systems — ensure uniform freezing and reduced product dehydration

- Compact spiral freezer design — suitable for modern production facilities with limited space

- Modular system configuration — scalable for increased productivity or configuration changes

- Automated control — minimizes operator intervention and the risk of errors

Cost of a spiral freezer compared to the return on investment

Every businessman thinks about profit, and we want to help you understand how profitable it will be for you to purchase this type of freezer equipment in Canada and the US.

Although the cost of a spiral freezer may initially exceed the cost of simpler systems, such as basic tunnel freezers, the return on investment is very important and, most importantly, makes it a very attractive purchase. What are the advantages of such a purchase for any fast food manufacturer in Canada and the United States?

- Energy savings,

- High throughput,

- Reduced waste

- Minimal floor space provide lower long-term operating costs

- Improved quality preservation

Manufacturer of our freezers has a case study where a self-stacking spiral freezer reduced energy consumption by 60% and manual cleaning costs by 80% compared to drum freezers.

Choosing the right spiral freezing system

If you are considering purchasing a spiral freezer, there are a number of factors to take into account:

- Do you need a spiral freezer for very fast freezing?

- Is one spiral freezer sufficient, or do you need a modular expansion?

- Space restrictions and availability of vertical space.

- Required freezing capacity in accordance with line speed and product type.