Industrial Spiral Freezer Systems (FR 1000): Essential for High‑Volume Fast Food Processing in Canada & USA

Fast food products have always been in demand in the Canadian and US markets. Many companies are looking to expand their product range with fast food products such as chicken nuggets, breaded fish fillets, battered snacks, and many others. The most important element in the preparation chain for such products is the freezer, which must preserve the product in the form you need. But what kind of refrigeration machine is needed for the fast food industry?

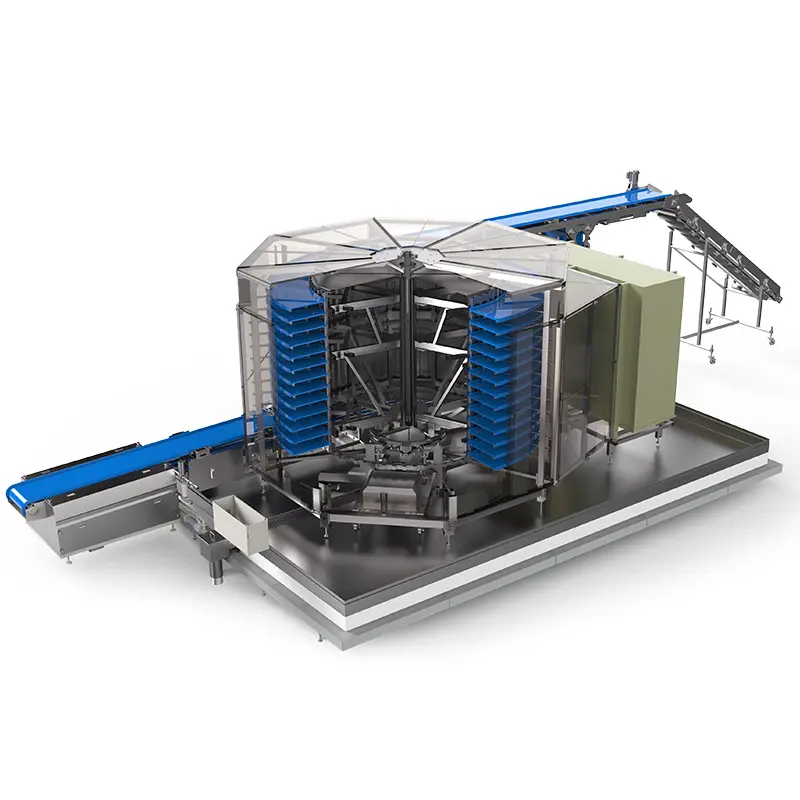

We have the answer for you: a spiral freezer system such as our Rozfood FR 1000, which is essentially a critical component. It provides fast (instant) freezing, consistent product quality, a compact design, and compliance with hygiene standards. As companies scale up production, they cannot compromise on freezing capacity or operational efficiency.

North American market overview and industry trends

Some interesting statistics: The global spiral freezer market in 2023 was estimated at US$4.5 billion, with North America accounting for approximately 38% of this revenue (about US$1.71 billion), driven by growing consumption of frozen foods, especially in the meat processing and ready-made meal sectors. According to the most conservative estimates, the North American market will grow at an average annual rate of 4.0–4.3% until 2030.

Growth is supported by rising demand for processed and frozen foods—US households alone account for more than US$72 billion per year in frozen food sales. It is therefore logical that industry research confirms the ongoing demand for efficient and energy-saving freezing solutions in meat, seafood, bakery, and ready-meal processing plants.

Why the FR 1000 Spiral Freezer is Ideal for Processing Plants

Choosing an industrial refrigerator is actually quite a challenge. Many manufacturers strive to produce not only highly efficient and energy-efficient models, but also compact ones, and our machine is just right for that. Here is some information about it.

Efficient freezing on an industrial scale

- High performance with compact vertical dimensions — suitable for IQF (individual quick freezing) lines for the production of breaded meat or seafood.

- North American processors report energy savings of ~17% per kg of product, increased throughput from ~1,200 to ~3,200 kg/h, and reduced cleaning downtime, as demonstrated on installations with multi-belt spiral freezers.

Integration, hygiene, and flexibility

- The modular, scalable design of the spiral freezer supports increased capacity as lines expand, ideal for multi-product facilities with allergen separation requirements.

- The design features sanitary finishes, easy-to-clean surfaces, and rapid defrosting capabilities to ensure compliance with all USDA/CFIA requirements and HACCP protocols.

Applications in fast food production

Potential buyers of the FR 1000 spiral freezer are active in the following areas throughout Canada and the US:

- Freezing breaded chicken products — nuggets, tenders, strips — with precise crust texture control

- Processing of fish fillets or seafood in multi-product production environments

- IQF freezing for vegetable or vegetarian snack production lines

- Integration into multi-line facilities offering allergen-free or gluten-free fast food products

This versatility meets market needs and industry trends that favor flexible, data-driven freezing solutions.

Key features and benefits

FR 1000 Spiral Freezer offers a huge number of benefits. To find out more, simply contact us. In the meantime, here are some of its technical specifications.

- Multi-level vertical belts for space saving

- Real-time temperature and air flow control

- Intelligent defrosting/pressure systems for uninterrupted operation

- Modular expansion with compact dimensions

- Clean-out design and food-grade materials

Here are some of the advantages that every business in Canada and the US can enjoy:

- Increased production capacity and line throughput

- Improved quality consistency — up to 80% reduction in complaints about freezing and clumping.

- Reduced energy costs and downtime for cleaning

- Modular design allows for cost-effective system scaling

- Ensures compliance with regulatory and audit requirements for traceability in accordance with USDA/CFIA

Frequently asked questions for industrial plant managers

Q: How effective are spiral freezers in high-capacity meat processing plants?

A: Very effective — North American poultry processing plants report a threefold increase in productivity (from ~1,200 to ~3,200 kg/h) and a reduction in cleaning time from 2 hours to less than 45 minutes thanks to the use of spiral freezers.

Q: Can the FR 1000 handle multiple product lines (e.g., allergen-free and standard)?

A: Yes. The modular design and fast cleaning cycles allow for different lines to be run.

Q: Are energy-efficient designs available?

A: Absolutely—modern systems use environmentally friendly refrigerants, improved insulation, and intelligent control systems to reduce energy consumption.

Q: What about local support in Canada/the US?

A: A warehouse in Canada and a support network in the US ensure fast delivery, installation, and access to spare parts.

For food processing plants in Canada and the USA expanding fast food product lines—such as nuggets, fillets, and breaded snacks—the FR 1000 Spiral Freezer System is an operational cornerstone. It delivers consistent quality, energy efficiency, scalable design, and regulatory compliance—exactly what modern facilities need to stay competitive.

Next Steps

Contact KOMPO North America Inc. today for a free production line consultation, demo video, or capacity-based proposal. Empower your facility with freezing technology designed for high-volume, clean-label, and precision IQF production.