Modern Slaughterhouse Equipment: Efficiency, Compliance, and Scale for Canada and U.S. Plants

After extensive communication with people who raise poultry and various livestock, we can confidently say that managing a poultry or meat processing plant in Canada or the United States today is more challenging than ever. From food safety standards to growing consumer demand, efficiency and regulatory compliance are critical. This issue involves many factors, but we will focus on one. Let's discuss investments in companies that manufacture slaughterhouse equipment in the US and Canada, which offer advanced and reliable solutions that can ensure profitable production and prevent costly downtime.

A few statistics: According to the North American Meat Institute, poultry and meat processing capacity in the US is expected to grow by 3–5% per year, driven by demand for ready-to-eat and processed protein products. In this environment, choosing the right equipment from US slaughterhouse equipment manufacturers is critical for both productivity and regulatory compliance.

Poultry Slaughterhouse Lines: why price quotes are important

It is important to know that when creating a new line or modernizing an existing plant, price quotes for poultry slaughter equipment or livestock slaughter lines allow managers or business owners to compare costs, performance, and after-sales service.

Modern lines include:

- Automatic evisceration stations

- Conveyor systems for transporting carcasses

- Stunning and slaughtering systems

- Cooling and chilling units

- Cleaning and disinfection systems

These systems, among others, reduce manual labour, improve hygiene, and increase productivity with lower labour costs and in small production facilities. Prices for chicken and livestock slaughter lines provide a clear picture of the investment in the line, helping processors plan their budget effectively and avoid hidden costs.

Choosing the right manufacturer

It would seem that all suppliers in Canada and the US are the same, but this is not the case. Leading companies manufacturing slaughterhouse equipment in Canada and the US pay special attention to the following aspects when manufacturing their equipment:

- Regulatory compliance – USDA and FSIS standards

- Automation and efficiency – high processing speeds with minimal downtime

- Durability – food-grade stainless steel and easy-to-clean design

- Local support – quick replacement of parts and maintenance

- Custom solutions from a US slaughterhouse equipment manufacturer – lines tailored to plant size, animal types, and production volumes A US slaughterhouse equipment manufacturer guarantees access to these benefits, as well as advice on process optimization and future expansion.

It is important to note that working with a reliable manufacturer of slaughterhouse equipment in the US and Canada guarantees access to these advantages, as well as advice on process optimization and future expansion.

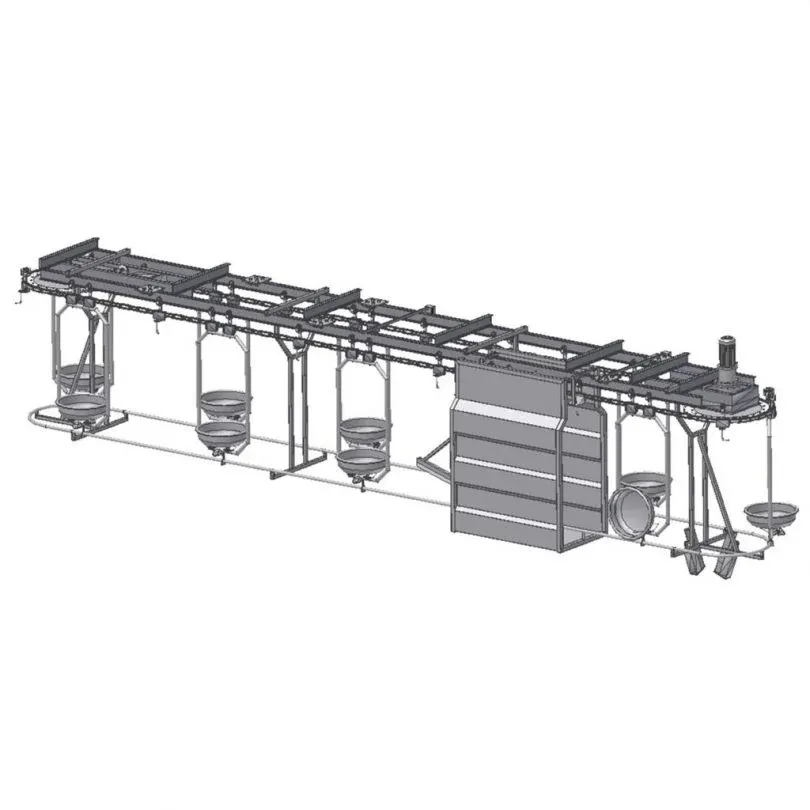

Key features of KOMPO North America Inc. slaughterhouse equipment

The list below is just a small sample of why you should order equipment from us.

- High-performance poultry and meat processing lines

- Stainless steel construction for food safety

- Integrated conveyors, cooling and cleaning systems

- Modular design for flexible line expansion

- Local technical support and spare parts available in stock

Benefits for meat and poultry producers in the US and Canada

- Improved production efficiency thanks to automated slaughter lines

- Reduced risk of contamination thanks to hygienic equipment design

- Scalable solutions for small and large processing plants

- Quick access to consumables and spare parts thanks to local warehouses

- Expert advice on plant layout and process optimization

Industry trends and prospects

The global trend is moving forward -toward automation. Automation in slaughterhouses in the US and Canada continues to grow and accelerate. Where is the benefit, you may ask? According to reports in Food Processing Technology Magazine, modern poultry processing plants that have implemented integrated lines are showing productivity gains of 15–25% and significant reductions in labour costs.

Due to stricter regulatory requirements and growing export demand, processors are increasingly investing in lines from US manufacturers of slaughterhouse equipment that combine efficiency, hygiene, and reliability.