Burger Former Machine ROZ B-12000

Burger Former Machine ROZ B-12000

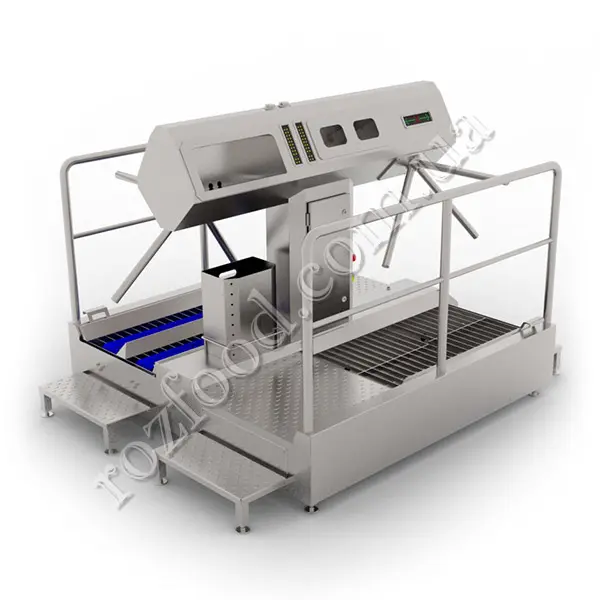

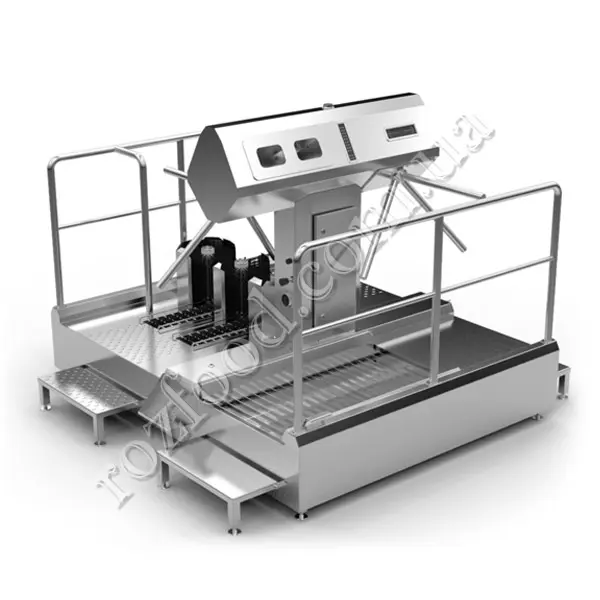

ROZ B‑12000 by KOMPO North America is a fully automatic burger forming machine designed for food processors in Canada and the USA who need reliable, high-output performance. This versatile unit can form up to 12,000 portions per hour, producing burgers, meatballs, croquettes, fish fillets, cheese-based shapes, and more. Its interchangeable drum allows for custom shapes ranging from 35 mm to 135 mm in diameter, with product thickness up to 34 mm (single form) or 62 mm (double form). All food-contact parts are made from stainless steel or certified food-safe plastics, ensuring durability and hygiene.

We have a wide range of equipment for food manufacturers in Canada and USA in our catalogue. Whether you are in the meat, dairy, pet food or any other industry, you can find equipment that will improve your bottom line and automate your processes. Also for sausage producers we have a wide range of clips, loops and casings at the best prices on the market, and the most important thing is that our consumables are universal and suitable for any equipment of our competitors.

The Roz-B-12000 burger’s former machine forms a wide range of products from such products as meat, fish, vegetables, butter, and cheese, as well as bakery products of various shapes and sizes.

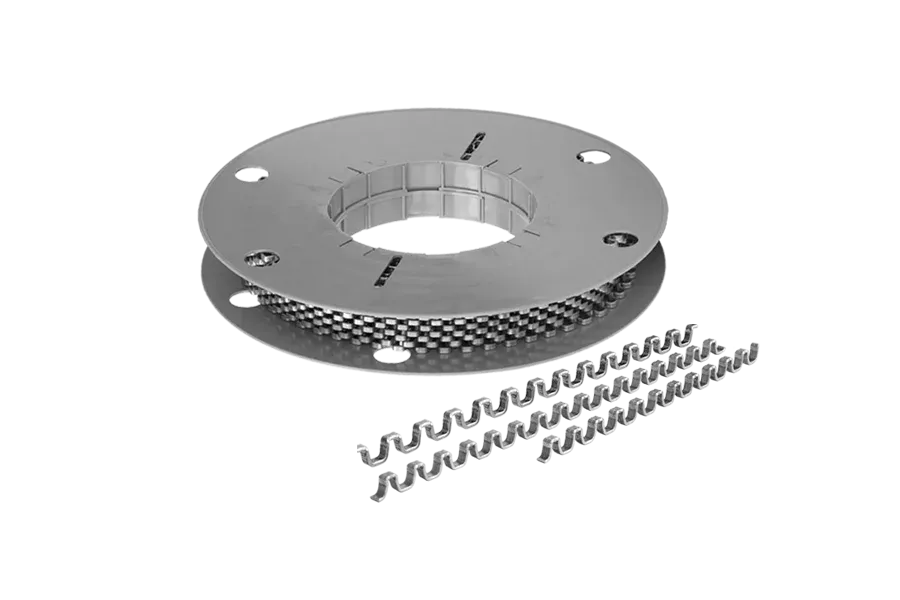

The burger former machine allows you to produce a wide range of products, thanks to the possibility of manufacturing a drum of almost any shape. The Shape of the product depends on the customer’s choice – it can be a traditional oval, circle, or rectangle, and the shape is made according to an individual sketch – fish, sticks, rectangles, squares, chicken breast, ellipses, etc.

The burger former machine, depending on the installed forming drum, can produce up to 12,000 products/hour. Products can be up to 34 mm high and up to 135 mm in diameter (single shape); and up to 62 mm (double shape).

All parts of the burger machine that are directly in contact with the product are made of stainless steel or food-grade plastic.

Automatic machines guarantee precise portioning and clear shapes of products.

Additional options:

- automatic cleaning device for cutting strings;

- automatic feeding device for paper backing (napkins);

- increased volume Hopper (75 kg);

- conveyor of increased length (750 mm).

Advantages of the device:

- ability to work with different types of minced meat;

- ability to produce large and small shaped products;

- the design of the hopper eliminates the leakage of minced meat;

- the presence of a limit switch that is triggered when the hopper is opened;

- degree of protection IP67;

- adjustment of the product output speed.

Technical specifications:

- Capacity – 12000 pcs / h (single form)

- Hopper capacity – 200 kg

- Supply voltage – 220 V

- Power – up to 1.75 kW

- Overall dimensions – 1000x800x2145 mm

- Weight – 220 kg