Full Barrier and Semi-Permeable (Smokeable) Casing

Full Barrier and Semi-Permeable (Smokeable) Casing

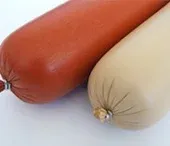

Our Full Barrier and Semi-Permeable Smokeable Casings are engineered to meet the needs of modern meat processing facilities that demand both functionality and flexibility. Designed for cooked and smoked sausages, these casings offer a balance between smoke permeability and shelf-life extension.

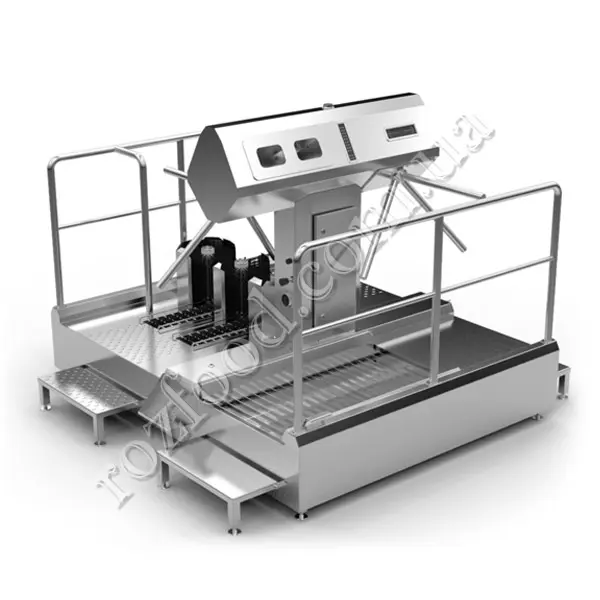

The full barrier smokeable casings are ideal when long product life and reduced oxygen exposure are a priority, while the semi-permeable versions allow for controlled smoke penetration and moisture exchange—enhancing flavor and appearance. These casings are suitable for automatic stuffing, linking, and clipping systems, ensuring a smooth and efficient production process.

KOMPO North America provides these casings to producers throughout Canada and the USA, with a reliable local inventory and expert customer service.

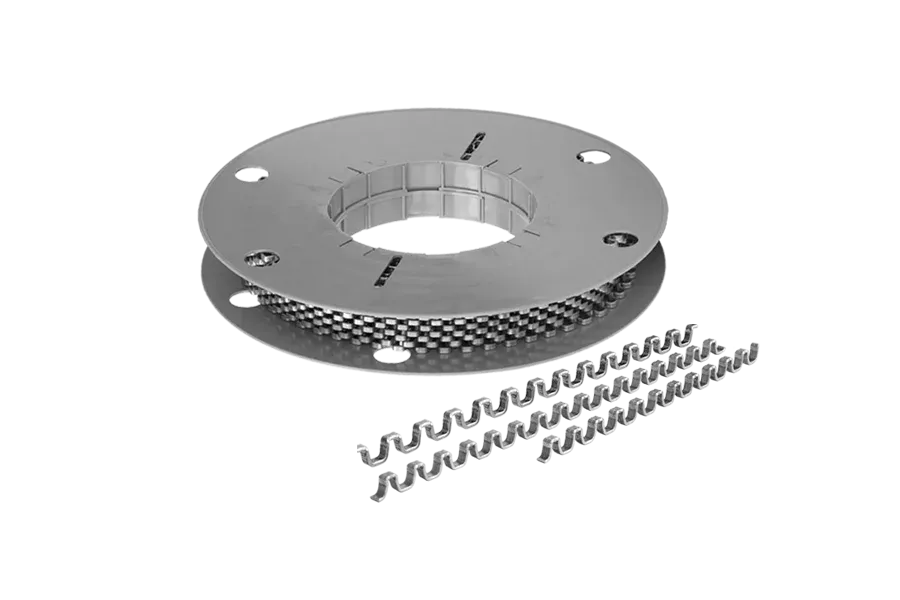

We have a wide range of equipment for food manufacturers in Canada and USA in our catalogue. Whether you are in the meat, dairy, pet food or any other industry, you can find equipment that will improve your bottom line and automate your processes. Also for sausage producers we have a wide range of clips, loops and casings at the best prices on the market, and the most important thing is that our consumables are universal and suitable for any equipment of our competitors.

KOMPO North America Inc. offers barrier one-layered casing for hot dogs, frankfurters and other products as well as barrier multi-layered casing for all kinds of sausages, pâtés, cheeses, butter, ice-creams and other food products.

Advantages of the casing supplied by KOMPO North America Inc.

Eliminates the risk of microbiological spoilage due to the use of materials that are insensitive to microorganisms.

High barrier properties with respect to the oxygen, which ensures retaining of the flavor and odor of the spices and product, eliminates the risk of chemical racidification of fat and oxidation of spices retaining the organoleptic properties and appearance of the products during the entire shelf life of the product.

Offers stable operation in the automatic mode due to the uniqueness of the equipment and processes, as well as due to its flexibility.

Ensures stable filling.

Minimum losses of weight during both, thermal processing and storage.

Great mechanical strength and elasticity.

Provides longest shelf life of the finished product.