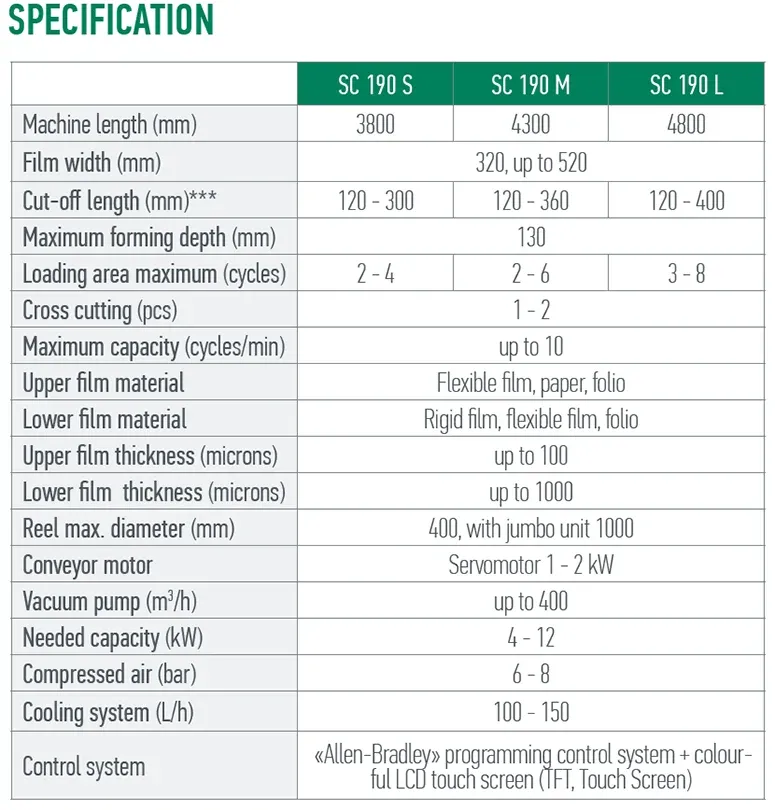

Thermoformer SC 190

Thermoformer SC 190

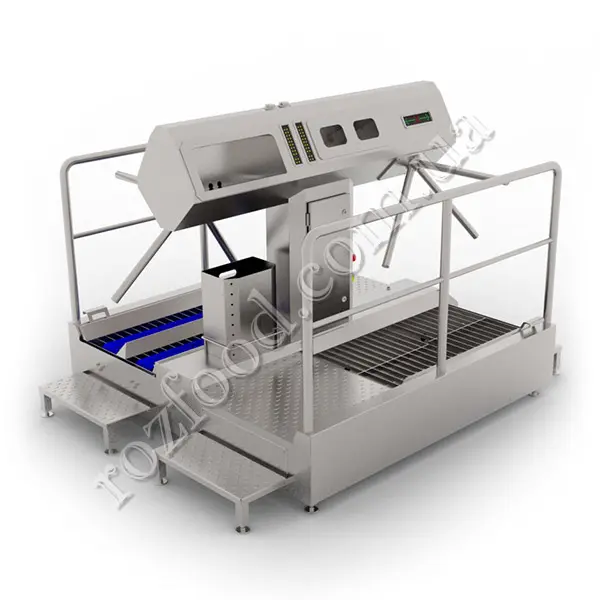

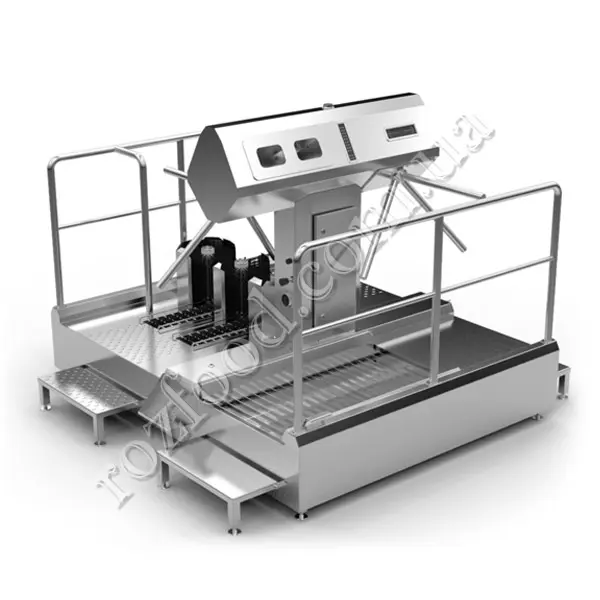

SC 190 Thermoformer is a compact and versatile packaging machine engineered for vacuum and modified atmosphere packaging (MAP) of food products. It offers reliable performance in processing meat, sausage, cheese, seafood, and prepared meals.

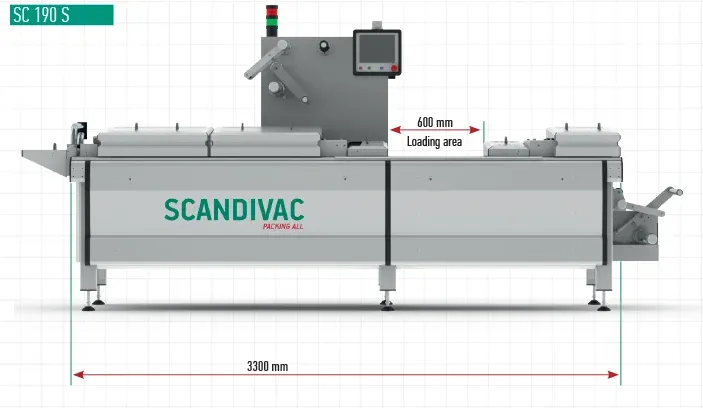

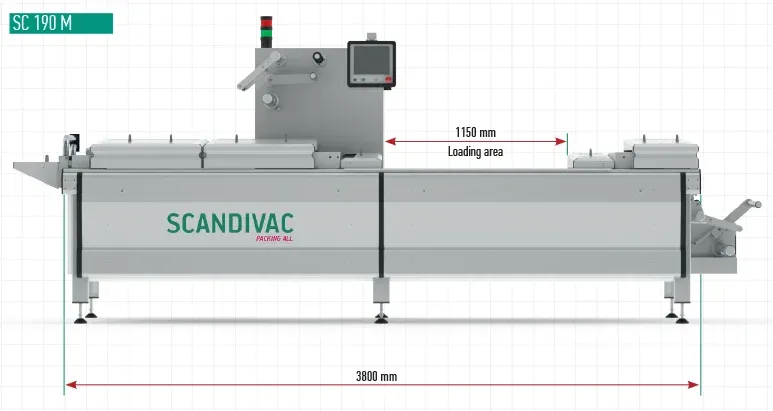

Designed with food safety and production efficiency in mind, the SC 190 features stainless steel construction, user-friendly touchscreen controls, and customizable mold configurations. Its space-saving footprint makes it ideal for facilities with limited floor space without sacrificing output or quality.

KOMPO North America proudly supplies the SC 190 across Canada and the USA, offering local technical support and parts availability to ensure maximum uptime for your production line.

Si necesita equipos más potentes, nuestro catálogo de estaciones de higiene cuenta con una gama de equipos que merece la pena que conozca. También disponemos de una amplia gama de equipos para plantas de procesamiento de alimentos en México, Colombia y América Latina. Y un punto más importante son los consumibles para procesadores de carne, nuestra calidad y precio le sorprenderán gratamente.

SCANDIVAC SC 190 is usable for small amount of products packaging. With very compact dimensions, it is very useful in limited areas.

Every single machine is manufactured according to the individual request; therefore it totally conforms with customers’ needs and wishes. By using tested technologies and electronical and pneumatic spare parts of European well known manufacturers, packaging machines provide safe, precise and stable work during many years of operation.

SCANDIVAC SC 190 can be used to pack wide range of products

Food – packing of meat, fish, salads, cheese, vegetables and other products

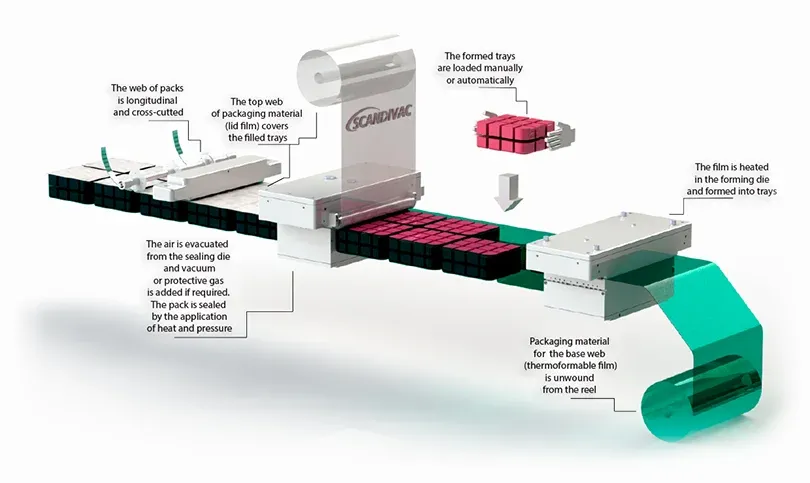

Type of packaging

• Only sealing of the package

• Vacuum and sealing

• Vacuum, gas and sealing

• „Skin” packaging

Types of cutting

• Longitudinal and cross-cutting

• Shape cutting

• Longitudinal perforation

• Cross-cutting perforation

Types of forming

• Only with compressed air

• With compressed air and vacuum

• With pre-heating of film

• With pre-heating of film and plugs

• Posiforming

Control system

• Colourful LCD touch screen

• Control elements from SMC Pneumatics, Schneider Electric, Allen Bradley, Busch and others

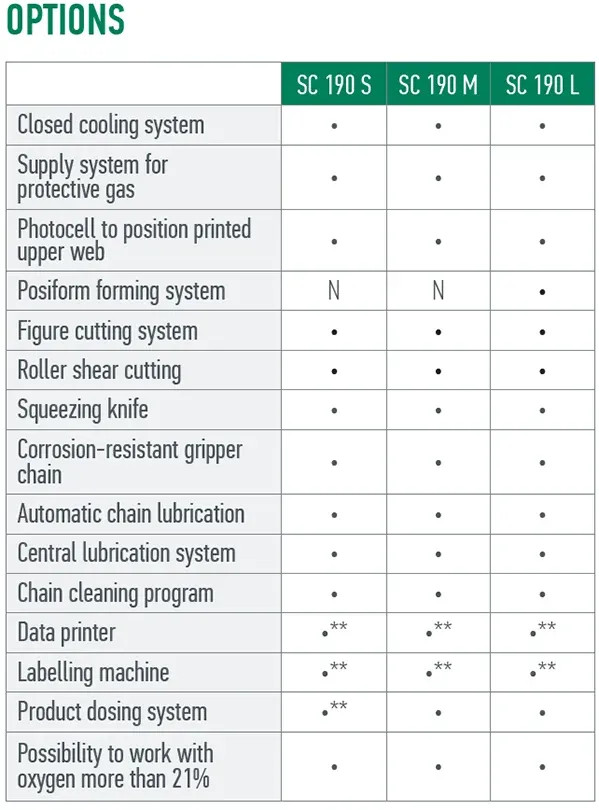

Potential options for SCANDIVAC machines

• Labeller

• Data printer

• Dosing system

• Pad placer

Features

- Solid stainless steel frame, for safe transportation and for strengthening of systems and mechanisms.

- Freely variable distance between moulds, giving a possibility to use dies with different cut-off lengths.

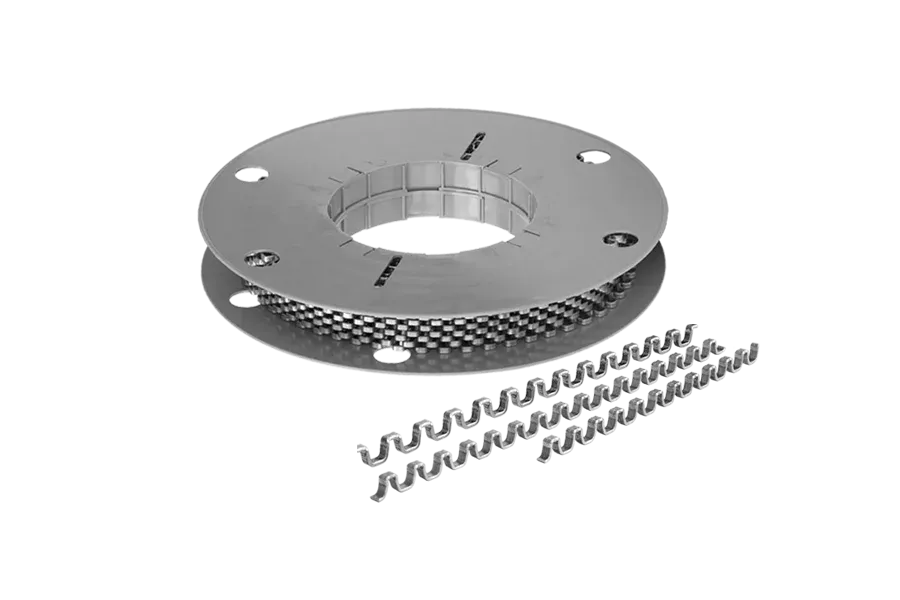

- Durable gripper chain guides casing.

- 4 or 6 point independent lifting mechanisms for dies with pneumatic drive and grease lubrication from a central location. Made from stainless steel and its moving elements are connected with bearings.

- All SCANDIVAC machines are equipped with servo drive system for gripper chain.

- Most of the spare parts are freely available on the market.