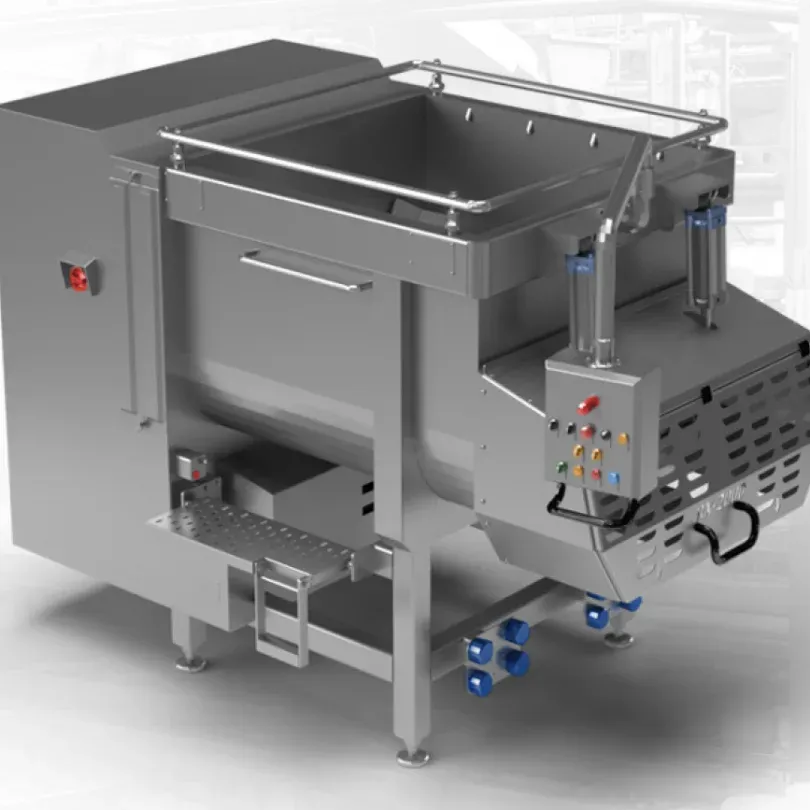

Washing machine TEB/TSB 60/80/100

Washing machine TEB/TSB 60/80/100

KOMPO TEB/TSB-60/80/100 Washing Machine is a highly efficient solution for thorough cleaning of sausage molds, trays, buckets and other similar containers used in food processing plants in the United States and Canada. Available in several sizes, this machine is designed to accommodate a variety of loads, making it ideal for small and large processing plants. With automatic wash and rinse cycles, the TEB/TSB provides fast, hygienic and economical cleaning. Made entirely of high quality stainless steel, these machines offer long service life and easy maintenance in demanding industrial environments.

At KOMPO North America Inc. you will find a wide range of washers and hygienic stations for businesses in Canada and the USA. Our catalogue also includes a wide range of equipment for meat, dairy, bakery, pet food and other industries. As well as high quality consumables for sausage producers and others who need clips, casings, loops, shrink bags and much more.

Washing machine TEB/TSB 60/80/100 equipped with doubled and multifunctional camera, and innovative electronic systems. Fast and efficient washing of a large number of large containers.

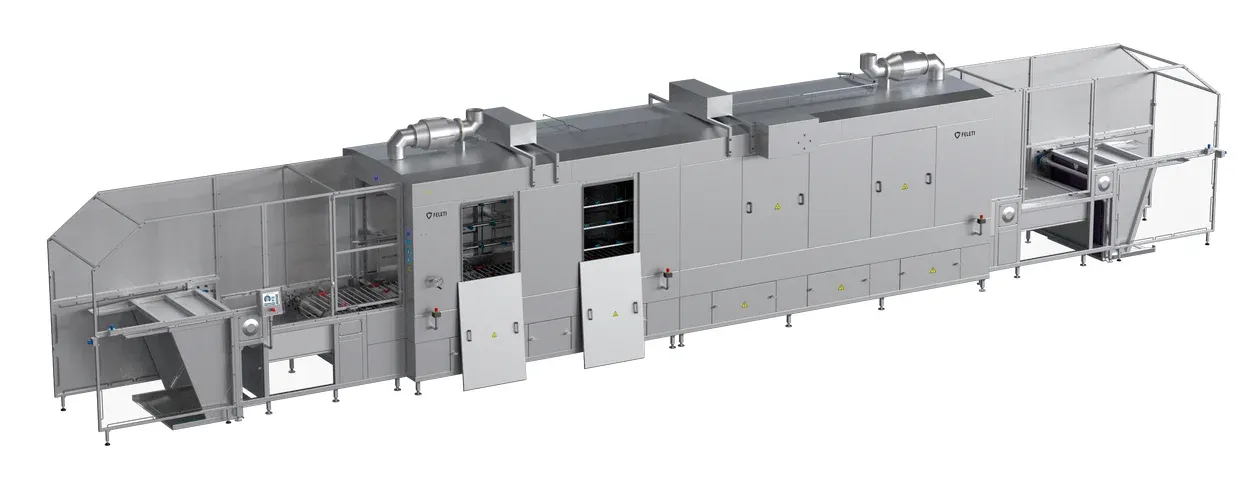

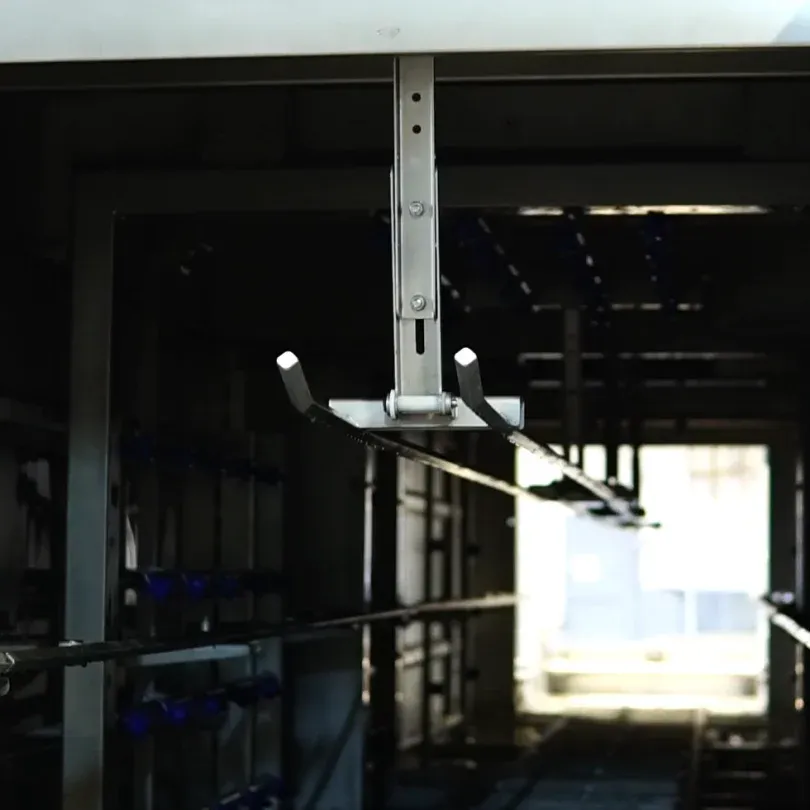

Washing module is designed to wash containers with a washing solution of the required proportion of water and washing solution under a certain temperature rinsed through jet nozzles. The solution is warmed up by thermo-electrical elements which are located in the washing module or by steam (existing steam hook-up required). The solution goes through the system of filters and is used as many times as required.

Rinsing module is designed to rinse the washing solution off with cold water under pressure of the totes through the system of jet nozzles. If sterilization is required, an option of Disinfection (the possibility of supplying the disinfectant through the nozzles in the rinsing section). Closed loop of water circulation: after rinsing water enters the cleaning tank of the main washing zone. Reservoir in the main washing zone overflows and excess of the detergent with surfacing dirt (fat, oil, foam) enters the sewer drain, thereby providing continuous renewal of detergent in the main reservoir.

High productivity of the machine is provided by strong mechanical impact of detergent on the boxing by means of high efficiency circulating pump. Washing area is equipped with a circulating pump, which provides a flow of detergent from the reservoir to the injectors under high pressure, in a large volume water circulation – up to 60 liters per minute.

BENEFITS

- Programmable touch screen display

- Rotational filter (optional)

- Powerful water pump

- Adjustable water consumption

- Adjustable water temperature

- Adjustable high and low pressure nozzles

- Adjustable conveyor speed

- Automatic washing soap dosing pump

- Custom made machines available