AUTOMATIC TRAY SEALER WITH VACUUM AND GAS TS-550

AUTOMATIC TRAY SEALER WITH VACUUM AND GAS TS-550

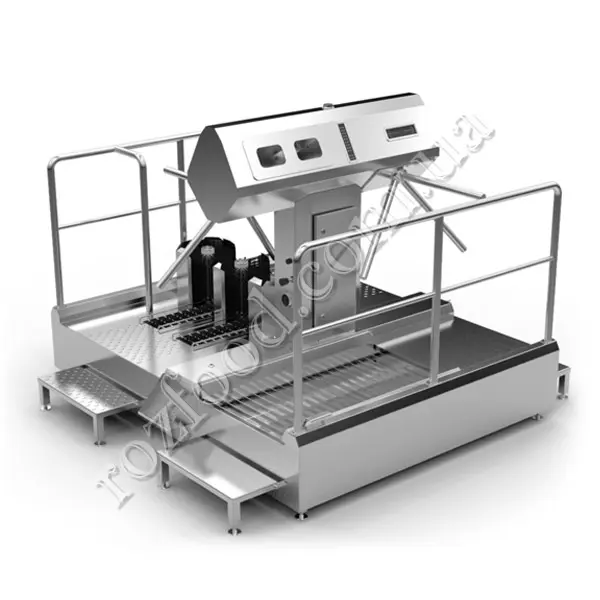

TS-550 Automatic Tray Sealer with Vacuum and Gas Injection is designed to ensure maximum shelf life and top-quality presentation for fresh, frozen, and ready-to-eat food products. Ideal for industrial and mid-size food processing plants, this machine offers high sealing precision, reduced oxygen levels, and MAP (Modified Atmosphere Packaging) capabilities.

Engineered for efficiency and flexibility, the TS-550 adapts to different tray sizes and materials, improving productivity while maintaining the highest hygiene standards. With easy integration into production lines, it’s an optimal solution for meat, poultry, seafood, dairy, and ready meals.

KOMPO North America Inc. proudly offers the TS-550 to food manufacturers across Canada and the USA, ensuring local support and reliable supply.

We have a wide range of equipment for food manufacturers in Canada and USA in our catalogue. Whether you are in the meat, dairy, pet food or any other industry, you can find equipment that will improve your bottom line and automate your processes. Also for sausage producers we have a wide range of clips, loops and casings at the best prices on the market, and the most important thing is that our consumables are universal and suitable for any equipment of our competitors.

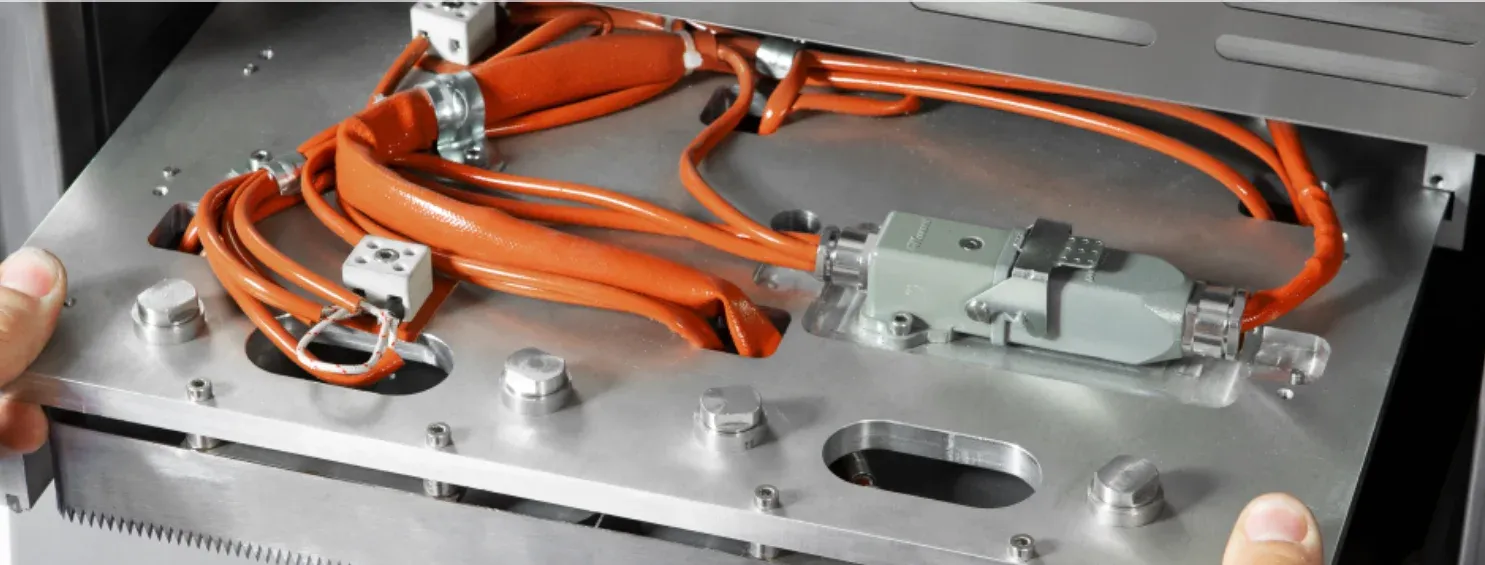

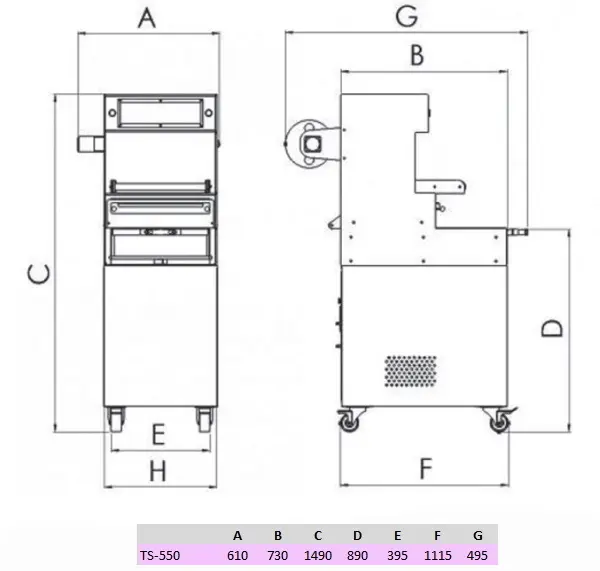

AUTOMATIC TRAY SEALER WITH VACUUM AND GAS TS-550 fast heating of the selected temperature, manufactured in stainless-steel AISI 304, die sets in anodized aluminum. Perfect for transporting food without loss of liquids or sauces. Compact and robust model equipped with gas flushing, digital control panel, easy change of molds that are interchangeable in a few seconds, gas flushing entrance and vacuum control by sensor, sealing temperature and time regulation. It allows working with different types of tray materials, PP, PET, Aluminum, etc. Maximum sealing surface 320×260 mm, film roll width 400 mm, power 1500 W.

TRAY SEALER TS-550 has VAC-STOP push button, finish the vacuum & continue the process, maintenance push button control, digital panel equipped with 99 memory programs, monitoring step-by-step of the cycle through LEDs and pump capacity 25 m³/h.

Standard molds with perimeter film cutting:

1/2 GN (320×260 mm) — 1 tray.

1/4 GN (260×160 mm) — 2 trays.

1/8 GN (168×130 mm) — 4 trays.

Standard molds with film cut at the back, non-perimeter:

1/2 GN (320×260 mm) — 1 tray.

1/4 GN (260×160 mm) — 2 trays.

1/8 GN (168×130 mm) — 4 trays.

Any type and shape of mold can be manufactured according to the customer trays.

Features

- Digital control panel.

- Vacuum control by sensor.

- Gas flushing entrance control by sensor.

- Sealing time regulation.

- Soft-air.

- VAC-STOP push button, finish the vacuum & continue the process.

- Maintenance push button control.

- 99 memory positions.

- Monitoring step by step of the cycle through led.