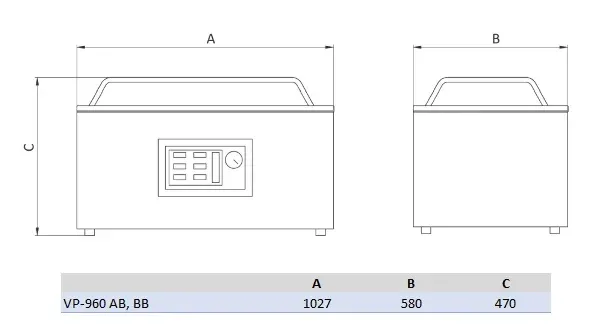

Vacuum packer table top AK-RAMON VP-960

Vacuum packer table top AK-RAMON VP-960

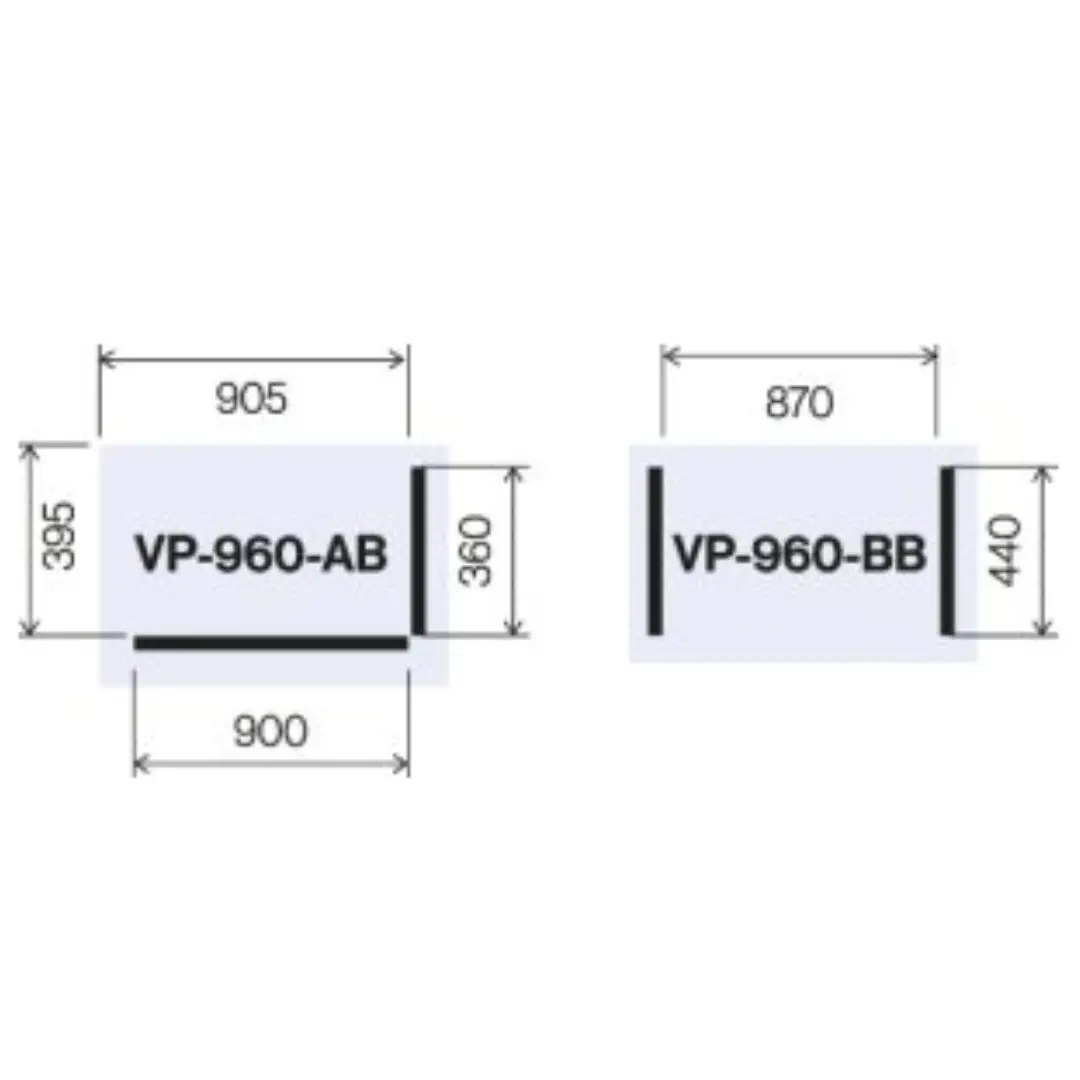

AK-RAMON VP-960 Tabletop Vacuum Packer is designed for efficiency and reliability in compact spaces. Constructed entirely from AISI 304 stainless steel, it ensures durability and hygiene compliance. The transparent lid allows for easy monitoring, while the digital control panel offers precise adjustments for vacuum and sealing parameters. Equipped with a robust 20 m³/h BUSCH vacuum pump, the VP-960 delivers consistent and rapid packaging cycles. Its double sealing bars and progressive atmosphere (Soft Air) system ensure product integrity, especially for delicate items. Optional features include gas flushing, sensor control, and bag cutting capabilities. Ideal for small to medium-sized food processors seeking a dependable and space-saving vacuum packaging solution.

We have a wide range of equipment for food manufacturers in Canada and USA in our catalogue. Whether you are in the meat, dairy, pet food or any other industry, you can find equipment that will improve your bottom line and automate your processes. Also for sausage producers we have a wide range of clips, loops and casings at the best prices on the market, and the most important thing is that our consumables are universal and suitable for any equipment of our competitors.

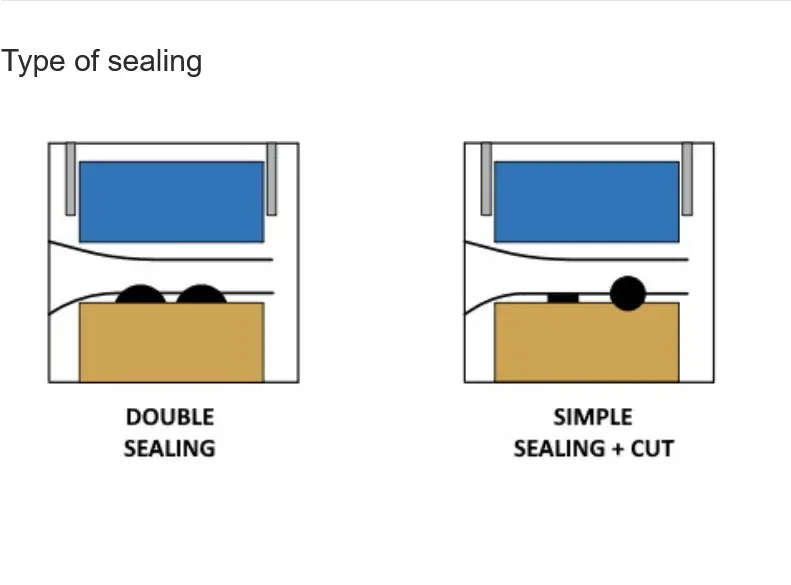

The tabletop vacuum packing machine by AK-RAMON VP-960 made of stainless steel. It has a transparent lid. The vacuum packer is equipped with digital control panel, Pneumatic sealing, Easy disassembly of sealing bars, polyethylene for faster packaging and easier bag placement and vacuum pump power 0.75 kW and productivity 20 m³/h. Double sealing type.

Accessories

Inclined plate for packaging products with liquids or sauces.

Vacuum connector in external buckets.

Options

Gas flushing entrance.

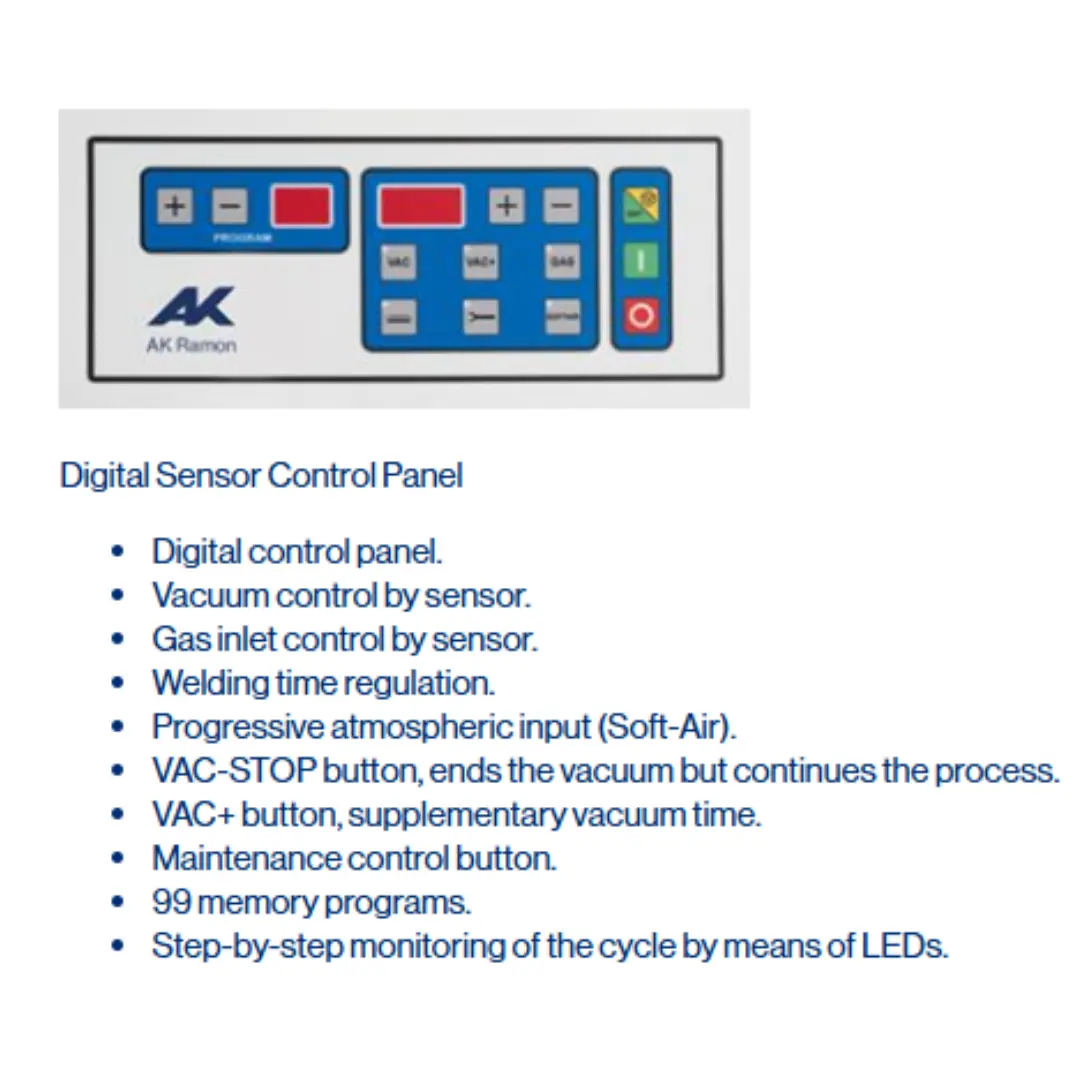

Controlled by sensor.

Cut off the bag.

Features

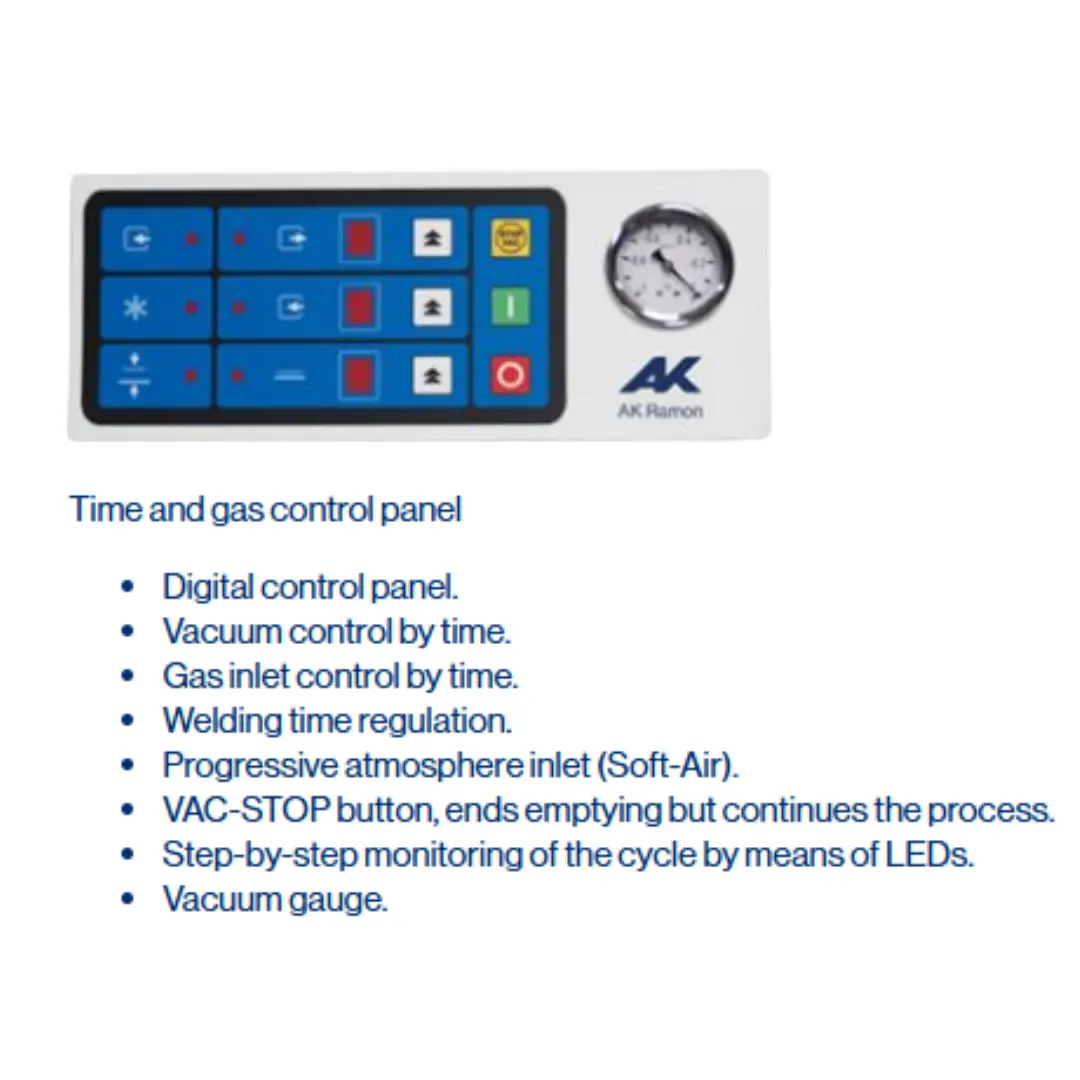

- Digital control panel.

- Vacuum control by time.

- Gas flushing entrance control by time.

- Sealing time regulation.

- Soft-air.

- VAC-STOP push button, finish the vacuum & continue the process.

- Monitoring step by step the cycle through lid.

- Vacuum gauge.