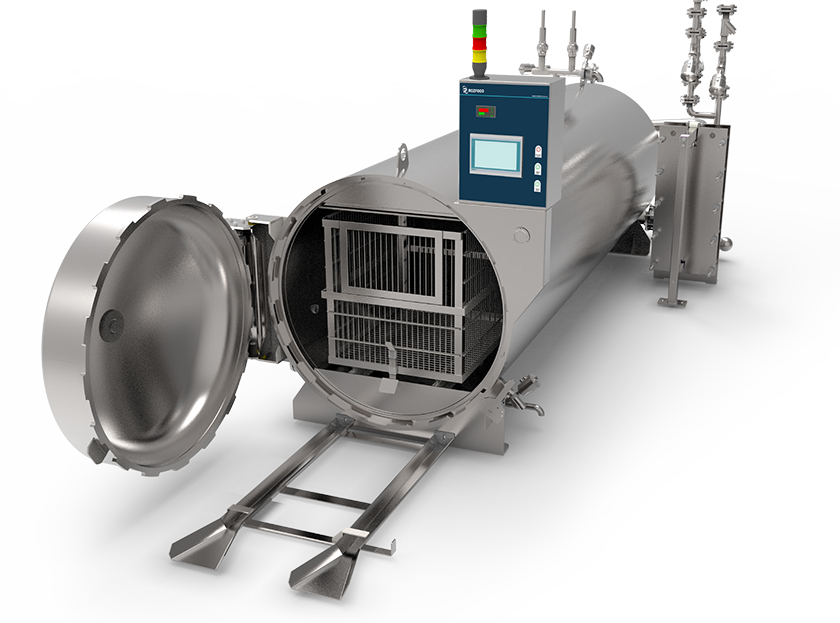

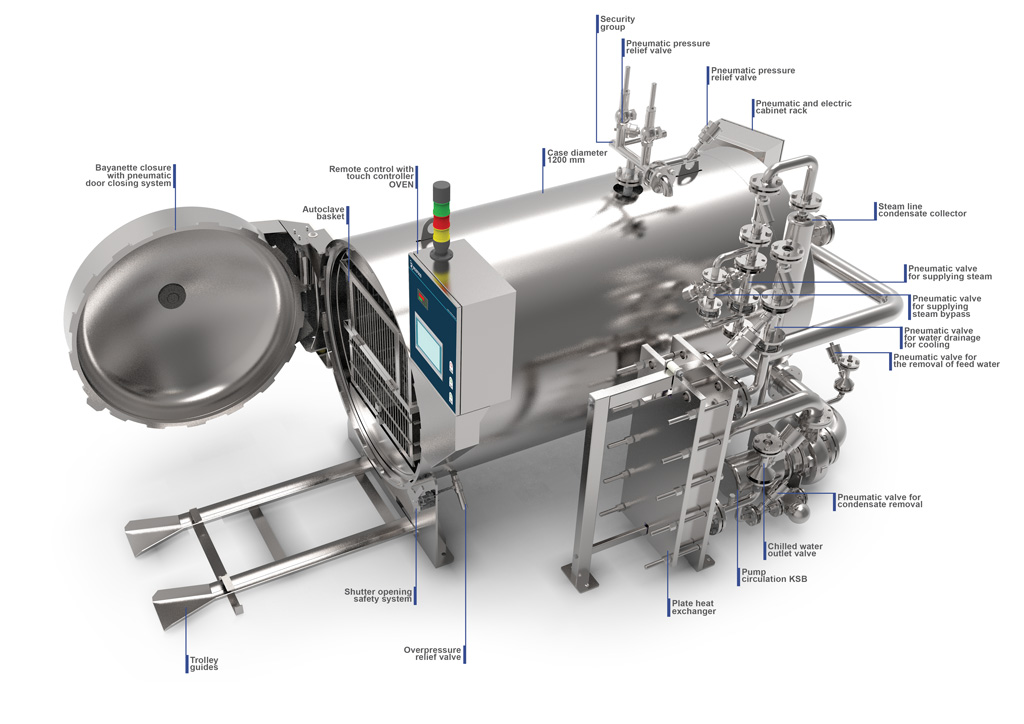

Sterilizing horizontal autoclave for 6 basket

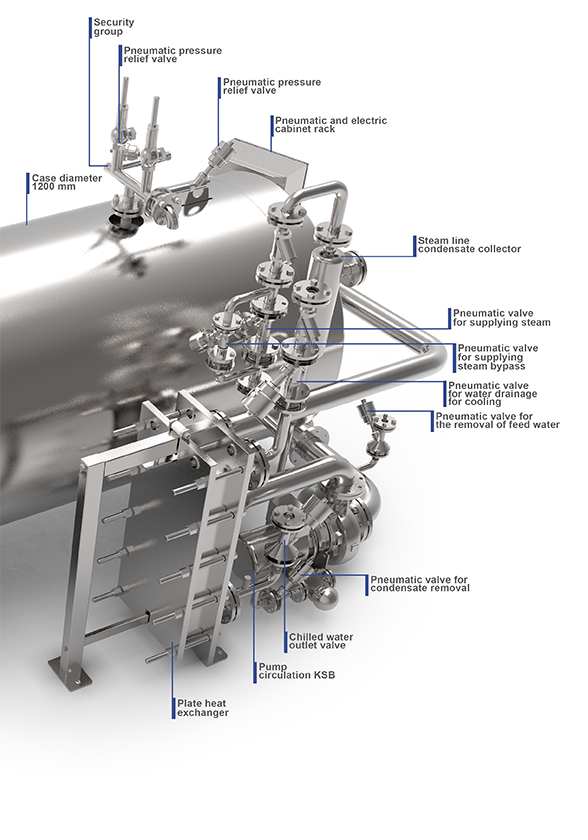

Due to the effectiveness of the suffocating system, the process of temperature acceleration and cooling of the product occurs evenly along the entire length of the autoclave, quickly and efficiently.

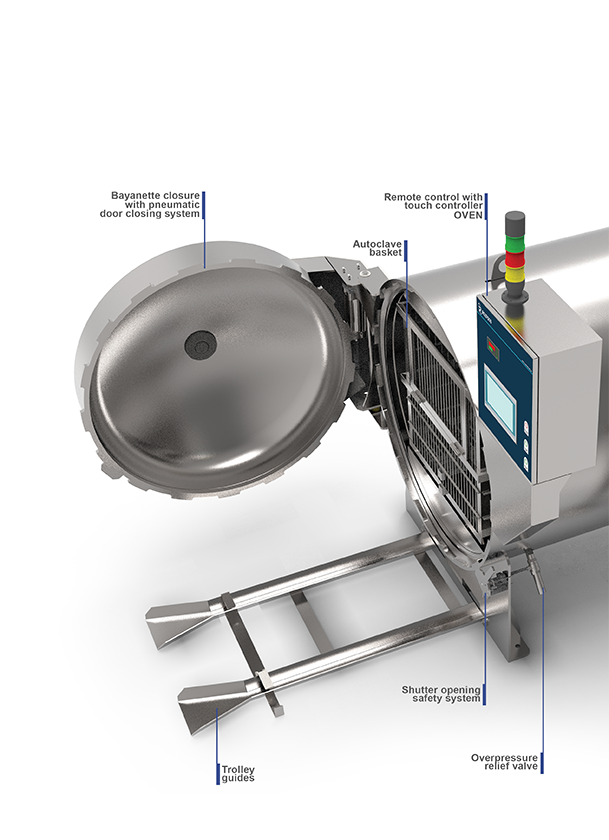

Operation is controlled by a touch screen, controlled by an industrial computer, which can store sterilization programs and histories of previous cycles.

The interface of the management program is distinguished by a high level of “usability”, a sequence that accelerates the learning process and ease of use. The autoclave is equipped with a three-level safety system, which makes it impossible to open the door if there is excess pressure inside the equipment.

The control system provides for both short-term and long-term power failure, and after its restoration, the system automatically adjusts the product processing program. It`s made of AISI 304 stainless steel. The body is covered with mineral wool and lined with a sheet of stainless steel to provide thermal insulation. Registration of pressure and temperature in the autoclave is carried out automatically and recorded on the memory stick. Control of system safety parameters during sterilization is carried out synchronously electrically, mechanically, and pneumatically.

- Capacity6 basket

- Power supplyby customer's request

- Type of heatingsteam

- Power, kWup to 11

- Materialfood grade stainless, acid-resistant steel

- Working volume, m36.7

- Steam supply, kg / hour900

- steam consumption per cycle, kg400

- steam pressure, Bar4-6

- The working pressure of the autoclave, MPa0.3

- Cold water consumption, m3/cycleup to 9

- The number of pre-installed programsup to 60

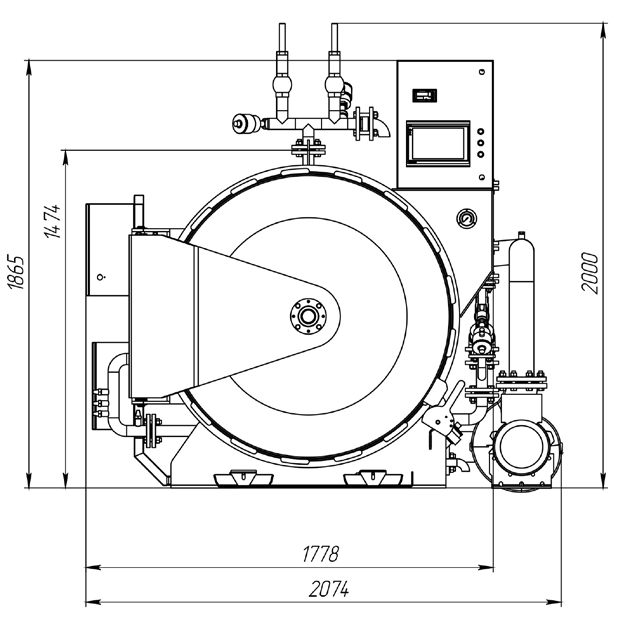

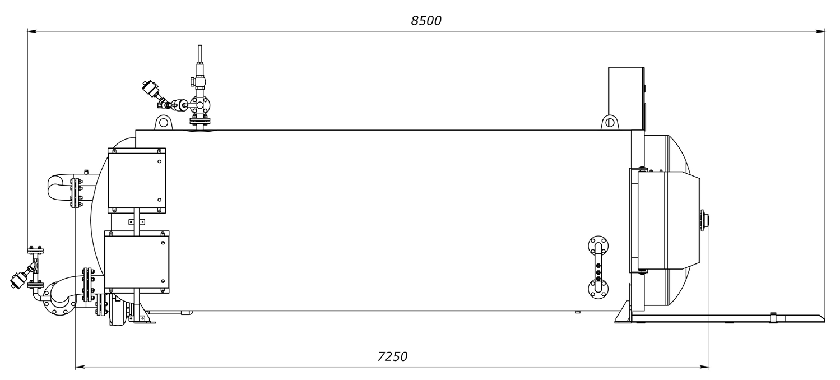

- Overall dimensions: Length*Width*Height, mm5250х2074х2000

- Net weight, kg~7250

Installations, customers’ personnel training, warranty and after warranty service provided by KOMPO North America Inc. certified technicians.

Consultations by phone and video calls are free of charge.

KOMPO North America Inc. is happy to provide its customers with the longest Warranty on the market. The extended warranty plans are available too.

Please, ask your sales person.

The spare parts are in stock in North and Latin American offices. Spare parts kits are available for any of the equipment you purchase from KOMPO North America Inc.

We are happy to help our customers succeed in their business, supplying the right and reliable machines to manufacture food products.

Please, contact us for details at [email protected] or Toll Free: 1-888-307-5330.

- Longest Warranty

- Preventive maintenance plans

- Spare parts kits

- Urgent service available