Pallet Washer MMP 100

Designed for washing pallets using a detergent solution at temperatures of up to 65°C, this machine facilitates the preparation of the cleaning solution within its tank. The solution’s temperature is automatically maintained throughout the washing process. The concentration of the cleaning solution can be automatically regulated or manually adjusted by the operator. Electric heaters are responsible for heating the solution. Furthermore, the solution is delivered to the container’s surface via a high-pressure system of collectors equipped with nozzles.

Rinsing:

Rinsing is conducted to flush the cleaning solution from the pallet surfaces using clean water delivered through a network of nozzles. This water supply is sourced from the centralized system of the facility.

Washing:

The cleaning solution is pumped via the nozzle system into the washing compartment, initiating the pallet washing process. The wastewater (comprising the cleaning solution) from the washing compartment and water used in the rinsing compartment are collected within the machine’s basin. After passing through the filtration system, this water is redirected into the tank for subsequent reuse. Simultaneously, as water flows in from the factory’s water supply system for rinsing, the tank experiences overflow. Consequently, any excess detergent solution, along with surfacing contaminants like fat, oil, and foam, are directed into the sewer drain. This mechanism ensures a complete renewal of the detergent within a period of 1.5-3 hours.

The design features include:

- Manufactured using stainless steel AISI 304 material for durability and hygiene.

- Automatic maintenance of the cleaning solution level in the tank.

- Cleaning solution filtration system enabling subsequent reuse.

- Automatic maintenance of the cleaning solution’s temperature.

- Digital temperature control for precise adjustments of the cleaning solution.

- Automatic maintenance of the cleaning solution concentration (additional function).

- Water recirculation system ensuring efficient usage.

- Programmable touch screen display

- One operator boxes return system (optional)

- Movable washing machine on wheels (optional)

- Rotational filter (optional)

- Powerful water pump

- Adjustable water consumption

- Adjustable water temperature

- Adjustable high and low pressure nozzles

- Adjustable conveyor speed

- Automatic washing soap dosing pump

- Custom made machines available

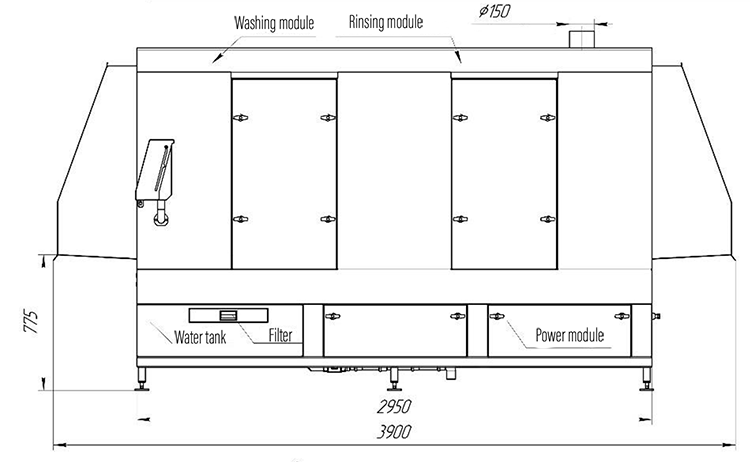

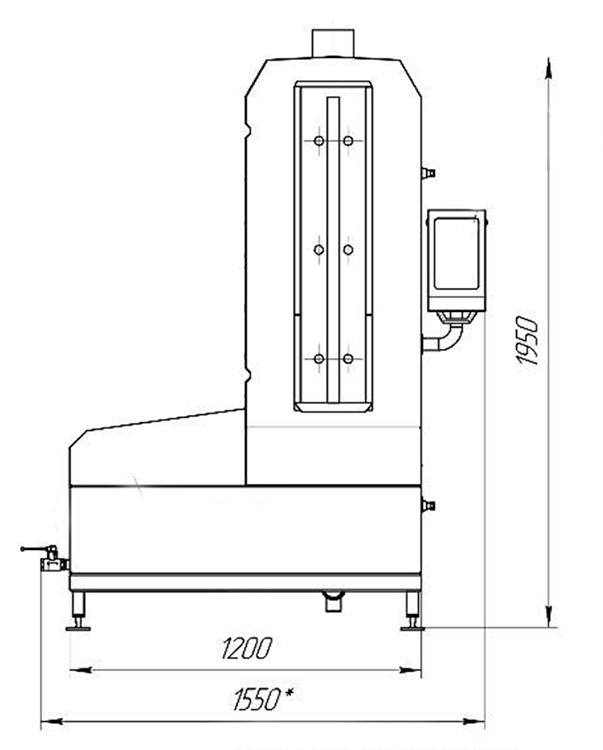

- ModelMMY 100

- Pallets size, mmLength: 1200Width: 1000Height: 120-160

- Power consumption, kW57

- Output per hour100 pallets

- Power supplyby customer's request

- Water inputG1

- Water outputDN 50

- Reservoir, liters400 liters

- Water pump power, kW7.5

- Heating elements power, kW48

- Overall dimensions: Length*Width*Height, mm3900 x 1550 x 1950

- Net weight, kg1250

Installations, customers’ personnel training, warranty and after warranty service provided by KOMPO North America Inc. certified technicians.

Consultations by phone and video calls are free of charge.

KOMPO North America Inc. is happy to provide its customers with the longest Warranty on the market. The extended warranty plans are available too.

Please, ask your sales person.

The spare parts are in stock in North and Latin American offices. Spare parts kits are available for any of the equipment you purchase from KOMPO North America Inc.

We are happy to help our customers succeed in their business, supplying the right and reliable machines to manufacture food products.

Please, contact us for details at [email protected] or Toll Free: 1-888-307-5330.

- Longest Warranty

- Preventive maintenance plans

- Spare parts kits

- Urgent service available