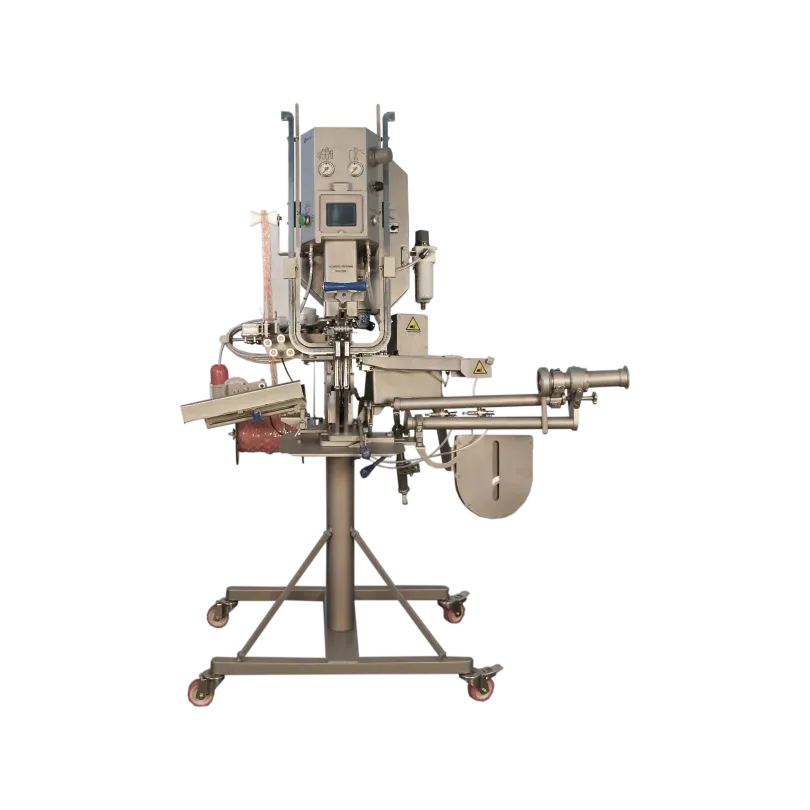

Mid Output Vacuum Stuffer KOMPO OPTI 2000-02 Cheese Version

Mid Output Vacuum Stuffer KOMPO OPTI 2000-02 Cheese Version

KOMPO OPTI 2000.02 Cheese Version is a mid-output vacuum stuffer specifically engineered for cheese production. Designed to handle medium-scale processing needs, this machine combines strong vacuum performance with gentle handling to preserve the structure and texture of soft and semi-hard cheeses. Its advanced filling system minimizes air inclusion and ensures accurate portioning, making it ideal for producers focused on consistent product quality.

Equipped with a user-friendly interface, hygienic design, and robust construction, the OPTI 2000.02 supports continuous operation in demanding environments. Whether packaging processed cheese, cream cheese, or other cheese-based products, this stuffer enhances productivity while meeting the highest hygiene and quality standards. Available for cheese producers in Canada and the USA.

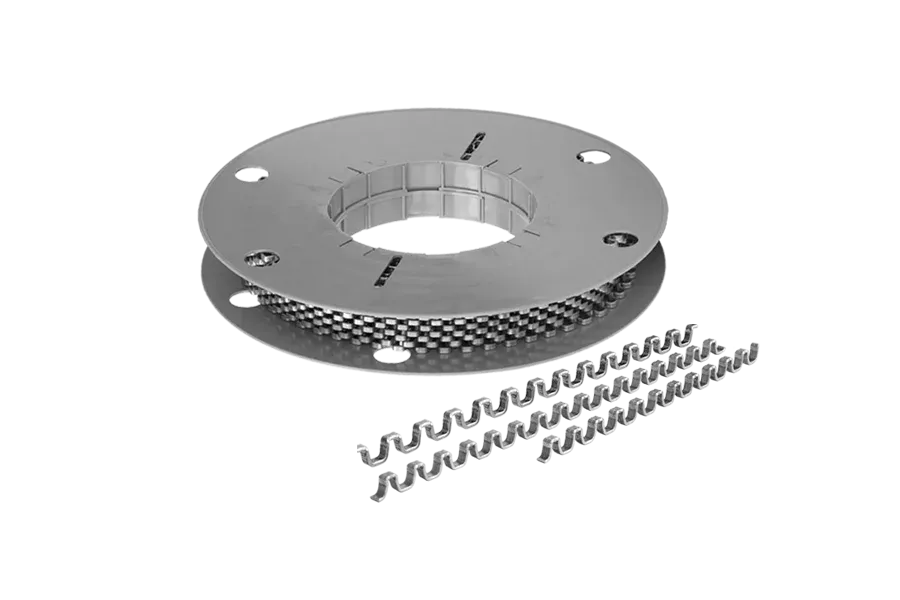

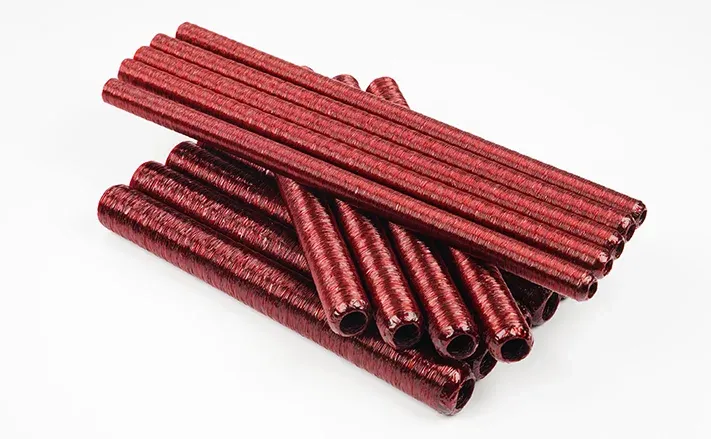

We have a wide range of equipment for food manufacturers in Canada and USA in our catalogue. Whether you are in the meat, dairy, pet food or any other industry, you can find equipment that will improve your bottom line and automate your processes. Also for sausage producers we have a wide range of clips, loops and casings at the best prices on the market, and the most important thing is that our consumables are universal and suitable for any equipment of our competitors.

- Possibility of high-quality production of all types of cheese chubs;

- optimal output of all types of cheese;

- high degree of vacuumization eliminating any porosity in all types of chubs;

- preservation of the melted cheese pattern under the casing and on the cheese cut;

- possibility of unitization with a clipper of any manufacturer;

- higher durability of work elements due to the original design of the displacer screws;

- efficient operation with liquid minced cheese due to the use of the Vacuum+ mode;

- programmable control system;

- mounting of an additional pair of special screws allows processing of

non-vacuumized cheese; - possibility of visual control of forcemeat availability in the cheese collector;

- possibility of heating of the stainless steel hopper and displacer housing

BENEFITS

- European and Japanese components

- Robust and reliable design

- Longest warranty on the market

- Intuitive touch screen control

- Active agitator

- Melted cheese temperature up to +3C

- Stainless steel design

- Meets all hygiene requirements in food industry

- Easy clean

- Tailored for cheese applications

- Vacuum filling system with minimized air inclusion

- Medium output capacity for flexible production

- Easy-to-use touchscreen control panel

- Durable stainless steel design for food-grade use

- Compatible with various attachments and accessories