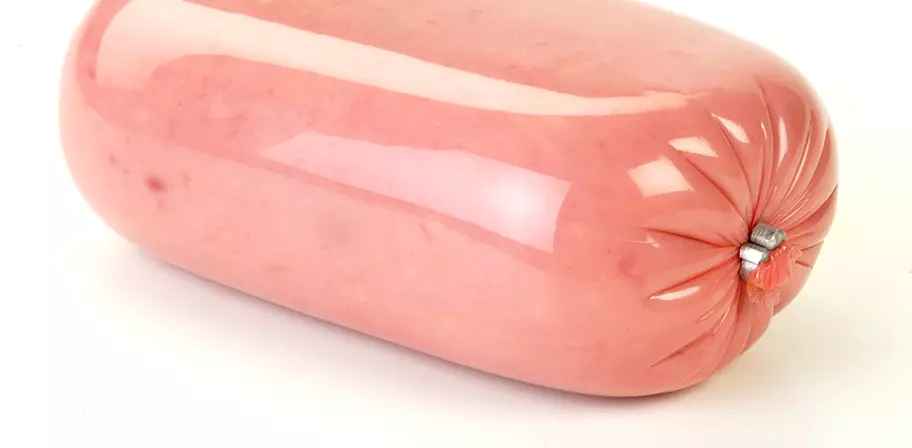

AMIFLEX T‑AM

AMIFLEX T-AM is a five-layer casing made of polyamide, polyolefin, and an adhesive (modified polyethylene) permitted for use in the food industry. The quality of the raw materials used for production of the AMIFLEX TAM casing is onfirmed by international quality certificates.

The distinctive features of the AMIFLEX T-AM casing that make it suitable for the modern production of restructured hams imitating whole-muscle products, with high yields, zero losses and long storage terms, are the following:

- enhanced adhesion of the casing to the stuffing mass, achieved through a special corona treatment of the inner surface of the casing;

- greater heat shrinkage in the machine and transverse directions, and better elasticity achieved through special parameters of biaxial orientation.

The AMIFLEX T-AM casing can be used for single- or doublesided single-color, multicolor or CMYK printing with the use of UV cured inks or inks based on volatile solvents.

- High elasticity of the casing combined with enhanced heat shrinkage makes it possible to accurately reproduce the required shape and obtain products with a smooth surface without «wrinkles» or folds.

- Greater adhesion to the stuffing mass prevents separation of the casing from the product and, consequently, formation of water pockets throughout the period of storage of the product.

- Low permeability to oxygen and water vapor ensured by a precisely selected combination of polymers and provides for the following advantages of the AMIFLEX T-AM casing:

- zero losses during the thermal processing and storage of meat and sausage products

- microbiological stability of the products during storage

- retardation of the oxidation processes that cause rancidification of fats and changes in the natural color of the meat product

- excellent selling appearance (no «wrinkles») of the finished products throughout the shelf life

- The mechanical strength of the AMIFLEX T-AM casing makes it possible to mold ball-shaped chubs with the use of high-capacity automatic and semi-automatic clippers at high production rates.

- Physiological safety the AMIFLEX T-AM casing is impervious to microbiological degradation because the materials used for their production are inert to the action of bacteria and mold fungi. This facilitates storage of the casing and improves the hygienic characteristics of both the casing itself, and of the sausage production.

- Casings typeAMIFLEX T‑AM

- Printing1-sided or 2-sided; full color. Printing with solvent inks and UV-printing are options.

- Forms of supplyIn rolls

- Forms of supplyIn shirred sticks

- Casing typeAMIFLEX T‑AM

- Casing caliber, mm80 – 200

Installations, customers’ personnel training, warranty and after warranty service provided by KOMPO North America Inc. certified technicians.

Consultations by phone and video calls are free of charge.

KOMPO North America Inc. is happy to provide its customers with the longest Warranty on the market. The extended warranty plans are available too.

Please, ask your sales person.

The spare parts are in stock in North and Latin American offices. Spare parts kits are available for any of the equipment you purchase from KOMPO North America Inc.

We are happy to help our customers succeed in their business, supplying the right and reliable machines to manufacture food products.

Please, contact us for details at [email protected] or Toll Free: 1-888-307-5330.