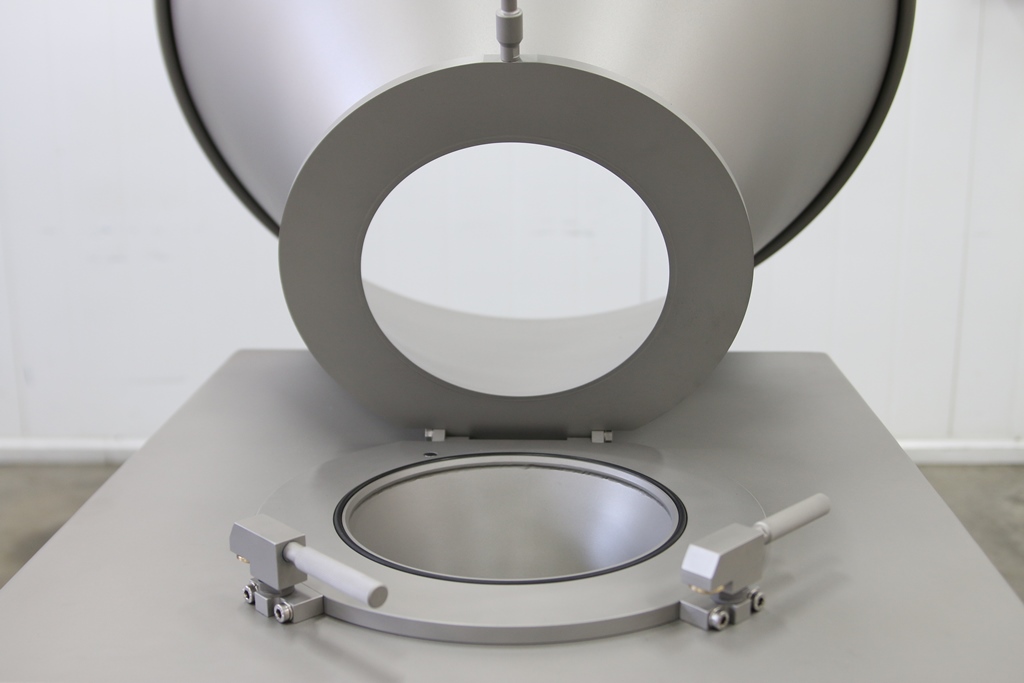

Vacuum stuffer KOMPO MINI 1500

The vacuum stuffer KOMPO-MINI is a perfect solution for small size businesses with high demands on the range and quality of finished products. Its compact dimensions and compatibility with clippers of any manufacturer make it indispensable for making high-quality products. At the same time, the high degree of vacuumization ensures the output of fine and premium quality products without pores. An option for heating of the stainless steel hopper and displacer housing allows the KOMPO-MINI to fill casings with melted cheese, butter, curds and other similar products.

- Possibility of high-quality production of boiled sausages and semi-smoked sausages with minimum forcemeat temperature of +3C;

- high degree of vacuumization eliminating any porosity in the product;

- preservation of the forcemeat pattern under the casing and on the sausage cut in semi-smoked sausages;

- higher durability of operating elements and parts due to the support grids;

- possibility of efficient operation with liquid forcemeats due to the use of the Vacuum + mode;

- possibility of unitization with manual and semi-automatic clippers of any manufacturer;

- mounting of an additional pair of special screws allows processing of

non-vacuumized forcemeats; - filling casings with melted cheese, butter, curds and other similar products;

- multipurpose applications, easy maintenance, reliability and low operating costs.

- European and Japanese components

- Robust and reliable design

- The longest guarantee on the market

- Produces any type of sausage

- Dual drive system for long life of filler

- 100L or 200L hopper convenient size

- Stainless steel design

- Meets all hygiene requirements in food industry

- Easy power wash clean

- Fully protected box in box control panel

- Spare parts kit

- Model1500

- Column loader FCAOptional

- Sausage linking deviceOptional

- Mincemeat temperature, °С+3 C

- Output at nominal speed, kg/hup to 7500 kg/h

- Dosage range adjustment, gr10-9999 gr

- Hopper capacity, liters100 L, 200 L optional

- Distance from floor to spindle axle, mm1020±20

- Output power, kW, maximum7,15

- Overall dimensions, mm, maximum: L*W*H1100*990*1765

- Net weight, kg560 kg

Installations, customers’ personnel training, warranty and after warranty service provided by KOMPO North America Inc. certified technicians.

Consultations by phone and video calls are free of charge.

KOMPO North America Inc. is happy to provide its customers with the longest Warranty on the market. The extended warranty plans are available too.

Please, ask your sales person.

The spare parts are in stock in North and Latin American offices. Spare parts kits are available for any of the equipment you purchase from KOMPO North America Inc.

We are happy to help our customers succeed in their business, supplying the right and reliable machines to manufacture food products.

Please, contact us for details at [email protected] or Toll Free: 1-888-307-5330.

- Up to 5 years Warranty against manufacturing defects;

- After-warranty service plans available;

- Training for operators;

- Customer’s technicians training available.